E-mail: [email protected]

Guide de sélection des plaques de mâchoire: Optimiser les performances pour votre opération de concassage

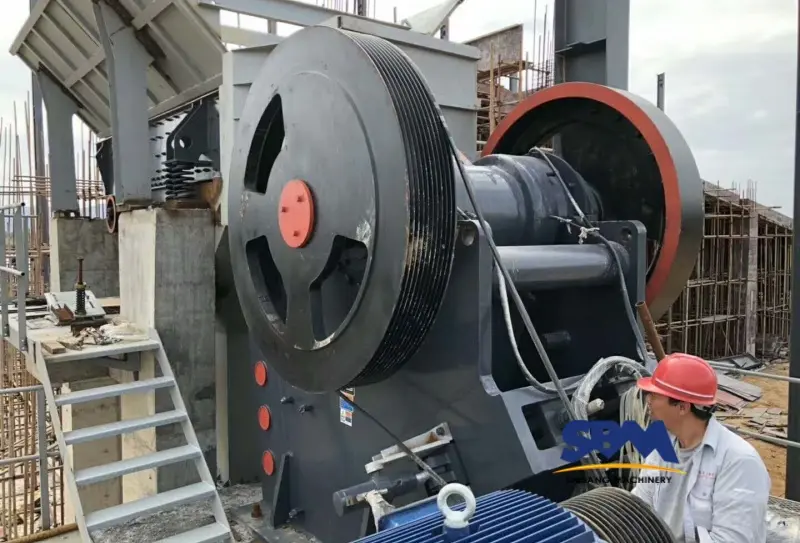

Choisir les bonnes plaques de mâchoire peut augmenter votreefficacité de concassage par 25-40% tout en réduisant les coûts de remplacement. Ce completguide de sélection des plaques à mâchoires explique comment la composition des matériaux, conception du profil des dents, et les conditions de fonctionnement déterminent la longévité des plaques. Que vous utilisiez un concasseur à mâchoires C6X ou des modèles plus anciens, ces informations vous aideront à prendre des décisions éclairées.

Facteurs clés dans la sélection des plaques à mâchoires

Choix de composition des matériaux

Les plaques à mâchoires modernes utilisent trois matériaux principaux:

- Acier au manganèse (14-18%): Idéal pour un usage généralapplications de carrière, résiste à 50-70 000 tonnes avant remplacement

- Alliage de fer chromé: 30% durée de vie plus longue dans les matériaux abrasifs comme le granit

- Céramique améliorée: Réduit l'usure de 45% dans les opérations à haute teneur en silice

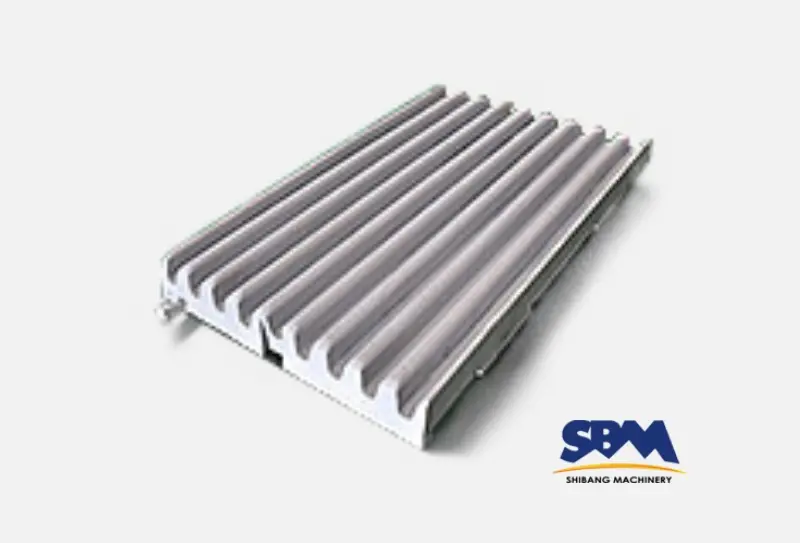

Considérations relatives à la conception du profil de dent

La configuration des dents de la plaque a un impact direct sur votremécanisme de travail du concasseur:

| Type de profil | Mieux pour | Plage de taille de sortie |

|---|---|---|

| Droit | Écrasement primaire | 150-300 millimètre |

| Agité | Réduction secondaire | 50-120 millimètre |

| Hybride | Aliments mixtes | 30-150 millimètre |

4-Processus de sélection des étapes

- Analyser les matières premières: Tester la dureté (Échelle de Mohs) et abrasivité

- Déterminer le type de concasseur: C6x Series Jaw Crusher nécessite des systèmes de verrouillage de plaque spécifiques

- Calculer la durée de vie économique: Équilibrer le coût initial par rapport aux tonnes broyées/$

- Vérifier la compatibilité: Vérifier les dimensions du système de montage (Tolérance de ±2 mm)

Synergie d'entretien: Santé des plaques et des concasseurs

Appropriéentretien du concasseur à mâchoires prolonge la durée de vie des plaques de 60%:

- Plaques de rotation 200-300 heures d'opération

- Maintenir les paramètres CSS corrects (affecte les modèles d'usure)

- Utilisez des outils d'alignement laser pour une installation précise

Étude de cas: Optimisation de la carrière de granit

Une opération brésilienne réalisée 32% réduction des coûts par:

- Passage des plaques standards Mn14 aux plaques Mn18Cr2

- Mise en place de mesures d'usure bi-hebdomadaires

- Synchronisation des remplacements avec les temps d'arrêt de maintenance programmés

Techniques de surveillance avancées

- 3Balayage d'usure D pour une analyse précise de l'épaisseur restante

- Modèles de prédiction du taux d'usure basés sur l'IA

- Tests de dureté par ultrasons pour la vérification des matériaux

Erreurs de sélection courantes

- Choisir des plaques bon marché nécessitant un remplacement 3 fois plus fréquent

- Ignorer la compatibilité des matériaux (Par exemple, contamination au zinc)

- Négliger les impacts du poids des plaques sur la cinématique du concasseur

La sélection stratégique porte ses fruits

MaîtriserSélection de la plaque de mâchoire nécessite de comprendre votre matériel, type de machine (comme les modèles C6X), et objectifs opérationnels. Associez ce guide à une maintenance préventive régulière pour obtenir 18-24 durée de vie des plaques d'un mois, même dans des conditions exigeantes. Souviens-toi: L’assiette optimale d’aujourd’hui peut différer demain – réévaluer les sélections comportant des changements importants.