ईमेल: [email protected]

निश्चित जबडा क्रशर वि गायरेटरी क्रशर: आपल्या प्रकल्पासाठी सर्वोत्तम निवड काय आहे?

प्राथमिक क्रशिंग उपकरणे निवडताना, दरम्यान वादनिश्चित जबडा क्रशर विजिरेटरी क्रशर अनेकदा उद्भवते. दोन्ही यंत्रे मोठे खडक कमी करण्यात उत्कृष्ट आहेत परंतु डिझाइनमध्ये लक्षणीय भिन्न आहेत, कार्यक्षमता, आणि अर्ज. हा मार्गदर्शक त्यांच्यातील फरक कमी करतो, वास्तविक-जगातील वापर प्रकरणे, आणि यासारख्या प्रकल्पांसाठी योग्य क्रशर कसे निवडावेठोस पुनर्वापर किंवा खाणकाम.

कोर डिझाइन फरक: ते कसे कार्य करतात

स्थिर जबडा क्रशर संरचना

अनिश्चित जबडा क्रशर संकुचित शक्ती वापरून कार्य करते. त्याचे दोन उभे जबडे—एक स्थिर (निश्चित) आणि एक जंगम-सामग्री तुटत नाही तोपर्यंत त्यांना दाबून क्रश करा. मॉडेल सारखेपीई 600 × 9000000000000000 खाणींमध्ये त्यांच्या साधेपणासाठी आणि विश्वासार्हतेसाठी लोकप्रिय आहेत.

Gyratory क्रशर यांत्रिकी

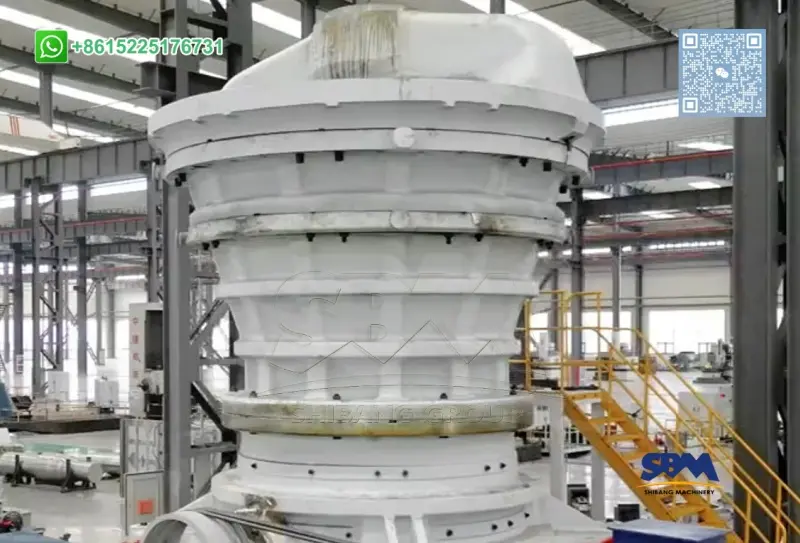

Gyratory crushers फिरणारे आवरण आणि अवतल पृष्ठभाग वापरा. मध्यवर्ती स्पिंडल गायरेट्स, सामग्री क्रश करणारी संकुचित क्रिया तयार करणे. ही यंत्रे अधिक उंच आणि मोठी आहेत, उच्च क्षमतेच्या खाणकामांसाठी त्यांना आदर्श बनवणे.

कामगिरी तुलना: कार्यक्षमता & आउटपुट

क्रशिंग क्षमता

- स्थिर जबडा क्रशर: सारख्या मध्यम-स्तरीय प्रकल्पांसाठी सर्वोत्तमठोस पुनर्वापर किंवा एकूण उत्पादन. ते अपघर्षक सामग्री चांगल्या प्रकारे हाताळतात परंतु वारंवार देखभाल आवश्यक असते.

- Gyratory crushers: उच्च थ्रुपुट (पर्यंत 14,000 टी/ता) मोठ्या खाणकामांसाठी उपयुक्त. त्यांचे सतत क्रशिंग सायकल डाउनटाइम कमी करते.

ऊर्जेचा वापर

उच्च-क्षमतेच्या सेटिंग्जमध्ये गायरेटरी क्रशर प्रति टन 15-20% कमी ऊर्जा वापरतात. तथापि, लहान ऑपरेशन्स पसंत करू शकतातनिश्चित जबडा क्रशर जसेमोबाइल जबडा क्रशर वि निश्चित जबडा क्रशर कमी आगाऊ खर्चासाठी.

देखभाल & ऑपरेशनल खर्च

परिधान पार्ट्स बदलणे

- स्थिर जबडा क्रशर: राखण्यासाठी स्वस्त. टॉगल प्लेट्स आणि लाइनर्स सारखे बदलण्यायोग्य भाग प्रवेशयोग्य आहेत.

- Gyratory crushers: कॉम्प्लेक्स असेंब्ली आवरण किंवा अवतल बदली दरम्यान डाउनटाइम वाढवते.

दीर्घायुष्य

जिरेटरी क्रशर हेवी-ड्युटी परिस्थितीत जास्त काळ टिकतात, असतानाजबडा क्रशर जसेPE 600×900 लहान प्रकल्पांसाठी किफायतशीर उपाय ऑफर करा.

ग्लोबल केस स्टडीज: जिथे प्रत्येक क्रशर चमकतो

केस 1: जर्मनी मध्ये ठोस पुनर्वापर

बर्लिन-आधारित रीसायकलिंग प्लांटने एनिश्चित जबडा क्रशर विध्वंस कचऱ्यावर प्रक्रिया करण्यासाठी. त्याचे कॉम्पॅक्ट डिझाइन आणि स्क्रीनिंग सिस्टमसह सोपे एकत्रीकरण त्यांच्या सुव्यवस्थित केलेठोस पुनर्वापर कार्यप्रवाह.

केस 2: चिली मध्ये तांबे खाण

चिलीची खाण वापरतेजिरेटरी क्रशर प्रक्रिया करण्यासाठी 12,000 दररोज टन धातू. त्याच वेळी, मशीनची उच्च क्षमता आणि कमी ऊर्जा वापरामुळे ऑपरेशनल खर्च कमी झाला 22%.

त्यांच्यामध्ये कसे निवडायचे

या घटकांचा विचार करा:

- प्रकल्प स्केल: लहान ते मध्यम? ए निवडानिश्चित जबडा क्रशर. मोठे खाणकाम? गायरेटरी निवडा.

- साहित्य कडकपणा: अपघर्षक समुच्चय? जबडा क्रशर चांगली कामगिरी करतात.

- अर्थसंकल्प: गायरेटरी क्रशरची आगाऊ किंमत जास्त असते परंतु दीर्घकालीन खर्च कमी असतो.

मोबाइल सेटअपसाठी, एक्सप्लोर करामोबाइल जबडा क्रशर वि निश्चित जबडा क्रशर तुलना.

अंतिम विचार

दोन्हीनिश्चित जबडा क्रशर विजिरेटरी क्रशर अद्वितीय शक्ती आहेत. जबडा क्रशर वर्चस्व असतानाठोस पुनर्वापर आणि मध्यम आकाराच्या खाणी, gyratory मॉडेल्स उच्च-खंड खाणकाम मध्ये उत्कृष्ट. तुमच्या प्रकल्पाच्या गरजांचे मूल्यांकन करा, साहित्य प्रकार, आणि माहितीपूर्ण निवड करण्यासाठी बजेट.

एक विश्वासार्ह क्रशर आवश्यक आहे? आमच्याबद्दल अधिक जाणून घ्यापीई 600 × 9000000000000000 किंवा आमच्या मार्गदर्शकाचे अन्वेषण कराgyratory crushers औद्योगिक अनुप्रयोगांसाठी.