Email: [email protected]

SP Series Vibrating Feeder

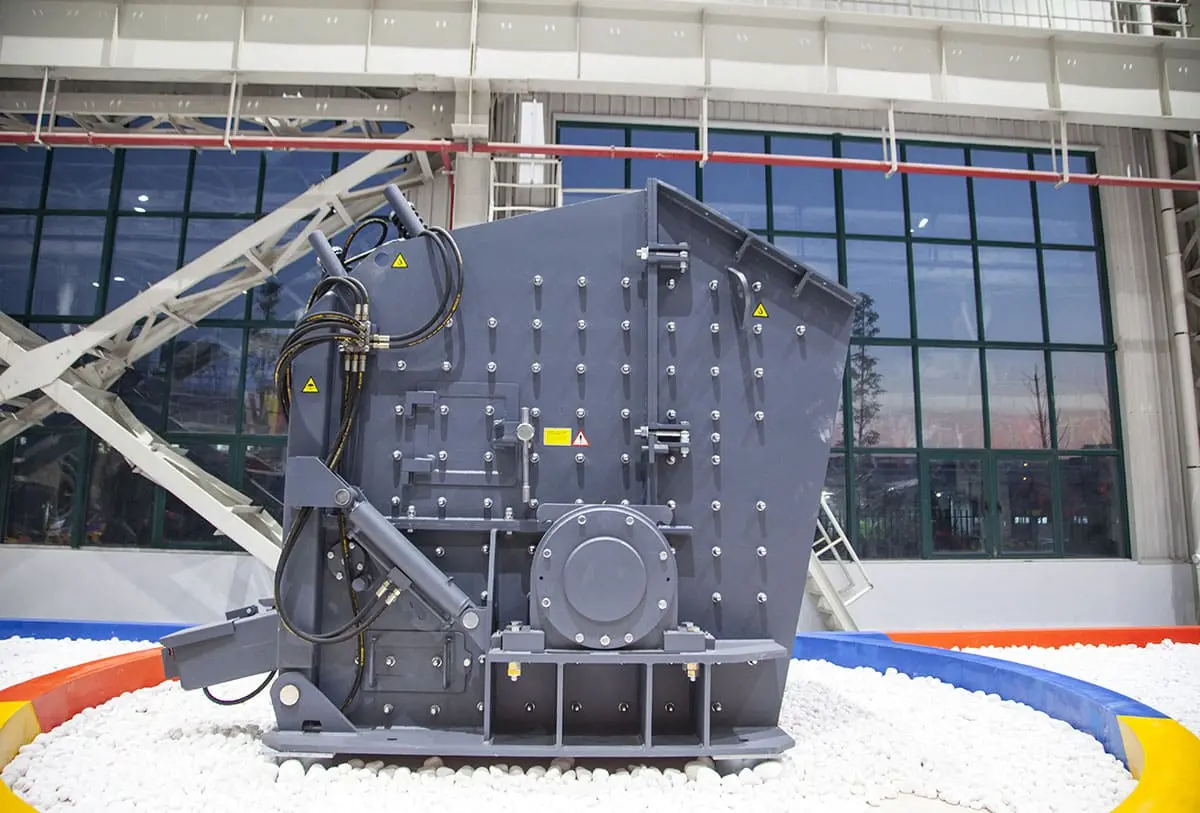

SP series is a new type of vibrating feeder developed by SBM on the basis of many years of practical experience in R & D, combined with the practical application of feeding and conveying equipment, and widely drawing on the independent R & D of cash metal at home and abroad. The equipment is simple and compact in structure, high in production capacity, reliable in operation and convenient in maintenance. It can be used to evenly and continuously feed small and medium-sized block, grain and powder materials from the storage bin to the receiving device. It is an ideal upgrading product of the traditional GZG or GZD Inertial Vibration Feeder.

Product Features: Double vibration motor drive, suspension or seat type installation, adjustable installation angle for 0-10 °

- Input Size: 0-500mm

- Capacity: 0-850t/h

- Applicable Material: granite, marble, basalt, limestone, quartzite, pebble, copper ore, iron ore, coal, etc.

Performance

Stronger Feeding Capacity

Using double vibration motor as the source of vibration, the vibration intensity is large and the feeding capacity is strong. It can better provide stable and sufficient feeding quantity for the secondary or tertiary crusher receiving materials at the rear end and improve the processing capacity of the equipment on the plant.

Convenient Adjustment of Feeding

The installation angle can be adjusted between 0-10 °, and the eccentricity of the vibration motor can be adjusted to change the magnitude of the exciting force, so as to achieve the effect of adjusting the feeding amount; the frequency converter can also be configured to adjust according to the demand, so as to realize the stepless adjustment of the feeding amount.

Better for Various Working Conditions

In the design, a variety of process requirements are fully considered, and the suspension type or seat type installation is adopted. On the premise of ensuring the feeding and reliable performance, the equipment is better used in various complex working conditions.

Simple Structure & Lower Maintenance Cost

The equipment is composed of three parts: tank body, support spring and vibration motor. The tank body adopts reinforced design, which is firm and reliable; the drive structure of Italian brand vibration motor is adopted without rotating moving parts, which is convenient and reliable for operation and maintenance.

Working Principle

SP series vibrating feeder adopts vibrating motor as the excitation source, and two vibrating motors are placed on the tank body at the rear or side. Its working principle is that two vibrating motors rotate in the opposite direction. When the motor rotates, the eccentric blocks at both ends of the motor generate the exciting force, and the driving equipment makes reciprocating linear vibration in the inclined direction of the feeding tank. When the component of tank vibration acceleration is greater than the component of gravity acceleration in the vertical direction, the materials in the tank are thrown up, and jump forward according to the trajectory of parabola. Every time the tank vibrates, the materials are thrown up once, so that the materials continuously jump forward at the tank vibration frequency, so that the materials are pushed slowly from the feeding end to the discharging end to achieve the purpose of feeding.

Product Parameters

| Type | Bin Size | Maximum Input Size(mm) | Capacity(t/h) | Vibration Frequency(r/min) | Double Amplitude(mm) | Installation Angle(°) | Power | Boundary Dimension |

| SP0816 | 800X1600 | 265 | 180-220 | 1470 | 3–4 | 0(0-10) | 0.75×2 | 1789×1284×1544 |

| SP0816Z | 800X1600 | 265 | 180-220 | 1470 | 3-4 | 0(0-10) | 0.75×2 | 1789X1327X918 |

| SP1220 | 1200X2000 | 400 | 400-500 | 1470 | 3-4 | 0(0-10) | 1.2X2 | 2217X1597X1548 |

| SP1220Z | 1200X2000 | 400 | 400-500 | 1470 | 3-4 | 0(0-10) | 1.2×2 | 2217X1731X970 |

| SP1623Z | 1600X2250 | 500 | 700-850 | 970 | 3-5 | 8(0-10) | 2×2 | 2467X2151X1211 |

Note:

Product pictures and parameters about models, data, performances and specifications on this website are for reference only. There is a chance that SBM may make changes on above-mentioned information. For specific messages, please refer to the real objects and user manuals. Without special instructions, SBM keeps the right to explain all data involved in this website.