Email: [email protected]

How to Choose Iron Ore Crusher: Your Ultimate, Practical Guide

Mining operations are under constant pressure to improve efficiency and cut costs, and nowhere is this more evident than in crushing. Having the right iron ore crusher isn’t just about saving time and money—it’s about laying the foundation for your entire plant’s productivity. This article walks through everything you need to know about how to choose iron ore crusher—from ore characteristics and technical parameters to practical advice drawn from real-world experience.

Why Choosing the Right Crusher Matters?

Picking the right iron ore crusher affects your whole production process. Making a good choice increases your output, cuts downtime, and helps your plant run longer and more smoothly. Choosing the wrong crusher can cause delays and unexpected repairs, which cost time and money. If you want reliable and efficient operation, you’re in the right place.

Understanding Your Iron Ore: The Foundation of Crusher Selection

Before hunting for machines, ask yourself:

- How hard is the iron ore? (For example, using the Mohs hardness scale)

- How abrasive is it? Tougher ores need crushers with stronger parts that resist wear.

- How much moisture does it contain? Wet ores might clog some crushers, so you need machines that resist sticking.

- What size is the ore when it enters, and what size do you want after crushing?

- Does the ore have special minerals or impurities, like silica or magnetite?

Quick Tips:

- For hard and abrasive iron ore: Use jaw crushers for the first crushing step and cone crushers for the second or fine crushing since they wear less.

- For softer or less abrasive ores: Impact crushers work well because they are flexible and efficient, but they don’t last as long with tough ores.

Crushing Stages Explained: From Boulder to Powder

Iron ore is processed in three main crushing stages:

Technical Parameters: What to Look for

Crucial specs when comparing iron ore crushers:

- Feed Opening Size: A bigger opening can handle larger rocks and offers more flexibility.

- Capacity (tons per hour): Make sure the crusher can handle the amount of material your plant needs to process.

- Output Size and Shape: The crusher should produce the right particle size and shape for the next steps, like mineral processing or smelting.

- Power Use: Look for crushers that use energy efficiently.

- Durability and Maintenance: Choose crushers with parts that last longer to reduce downtime and repair work.

- Automation and Controls: Modern control systems help keep operations steady and reduce errors.

- Noise and Dust Control: These features are important for safety and meeting environmental rules.

Sample Parameter Table: SBM Crushers

| Model | Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kW) | Application |

|---|---|---|---|---|---|

| HJ Jaw | ≤600 | ≤25-30 | 100+ | 110-200 | Primary, coarse |

| CS Cone | ≤300 | ≤15-25 | 150-800 | 185-400 | Secondary/fine |

| CI5X1315 | ≤600 | ≤25-50 | 250-350 | 250-315 | Medium, abrasive |

| HPT300 Cone | ≤150 | ≤10-12 | 120-350 | 200-250 | Fine, high volume |

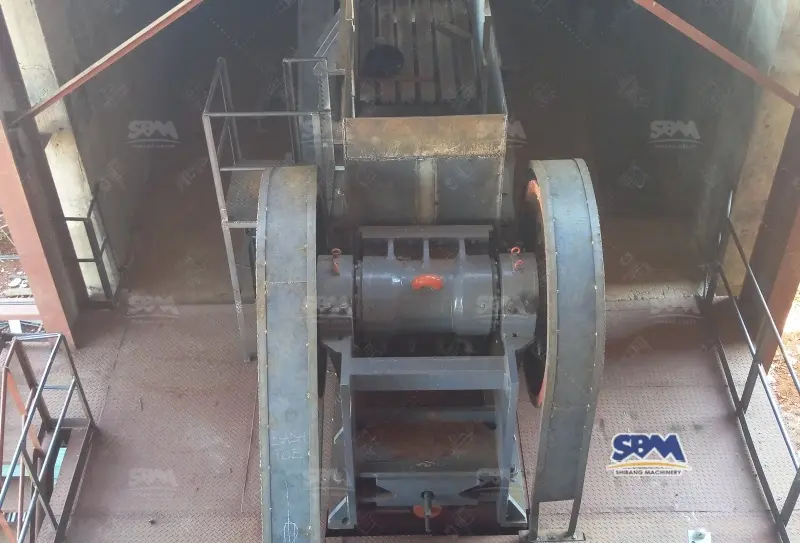

Iron Ore Crusher Types: Which One’s for You?

Let’s break down the most common crusher options—no jargon, just the facts.

Cone Crusher

- Pros: Handles a large amount of material, works well for the second and third stages of crushing, produces good-shaped and fine particles. Hydraulic systems make maintenance easier.

- Cons: Costs more upfront and is a bit more complex to maintain.

- Best for: Middle to fine crushing of hard and abrasive ores.

Impact Crusher

- Pros: Works great with softer, lighter ores and when the shape of crushed pieces is important. Easy to adjust output size.

- Cons: Parts wear out faster, so it’s not good for very hard or abrasive ores with lots of quartz or silica.

- Best for: Soft to medium ores that need a good shape. Not suitable for raw iron ore straight from the mine.

Crusher Selection Checklist: Questions to Ask

- What is my input feed size and target output size?

- What capacity (tons/hour) is necessary?

- Is the ore hard, abrasive, wet, or sticky?

- What’s my budget for equipment and ongoing maintenance?

- What is the power supply and infrastructure on-site?

- How critical is after-sales support and local service part availability?

Real-World Iron Ore Crushing Plant Configurations

Example 1: Thailand 1000TPD Plant

Example 2: 14 Million TPY Plant

| Parameter | Value |

|---|---|

| Feed Size | ≤900 mm |

| Finest Output | ≤12 mm |

| Jaw Model | 900×1200 |

| Cone Model | HPT300 |

| Daily Output | 40,000+ t |

| Crusher | Key Specs | Best For |

|---|---|---|

| HJ Jaw | Wide cavity, 1000 TPY+ | Coarse, abrasives |

| CS Cone | Spring/Hydraulic | Secondary, hard stone |

| HPT Cone | Multi-cylinder, fine | Tertiary, fine grading |

| CI5X Impact | High-speed, cubical | Soft, mid-hard ores |

Maintenance and Service: Don’t Overlook the Details

A high-efficiency iron ore crusher is only as good as its uptime. When deciding how to choose iron ore crusher, prioritize:

- Parts life and local availability—never fun dealing with week-long waits!

- Ease of routine maintenance—look for hydraulic adjustments, quick-change liners, and convenient access points.

- Automation—smart sensors save headaches and prevent breakdowns.

- Supplier support—choose brands with robust service networks.

Fixed or Mobile Iron Ore Crushing Plants?

- Fixed Plants: Durable, powerful, good for long-term sites; higher initial investment.

- Mobile Plants: Flexible, quick to deploy, great for scattered/moving ore bodies; modular designs now rival fixed plants for many scenarios.

Cost of Ownership: The Long Game

Don’t fall for the “cheapest machine” mindset. Consider:

- Initial purchase price

- Power consumption

- Wear parts and repairs

- Downtime costs

- Resale value

Surprisingly, a slightly higher initial investment in a robust, efficient crusher can pay you back many times in lower operating costs and smoother operation.

FAQs on How to Choose Iron Ore Crusher

Opt for crushers with open designs and anti-clogging features. Hammer or roller crushers sometimes suit wet, sticky feed.

Cone or gyratory crushers with high throughput capacity and robust construction win here.

Yes, especially the new modular mobile lines. They are particularly handy for geographically dispersed mining operations and can be quickly set up and relocated as needed.

Final Thoughts: The Smart Crusher Choice

Choosing the perfect iron ore crusher is a balancing act—capacity, ore type, particle specs, and cost all matter. Don’t skip looking at maintenance needs or after-sales support. With this guide, “how to choose iron ore crusher” is no longer a mystery—just a practical, step-by-step process where your knowledge, experience, and a little expert help make all the difference. May all your rocks be crushed to spec!

Remember to contact reputable manufacturers for tailored technical advice and test runs against your ore sample before buying. Good luck and happy crushing!