Email: [email protected]

30tph Jaw Crusher for Sale | High-Efficiency SBM Crusher

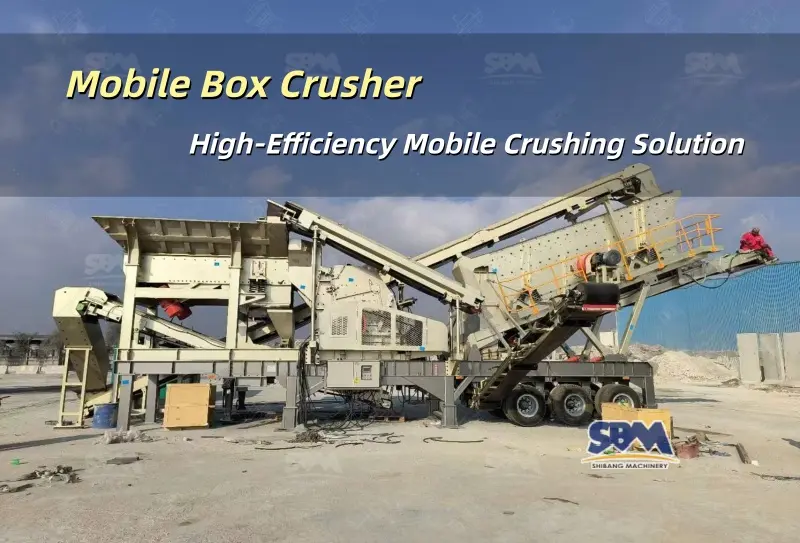

When mining companies plan to invest in crushing equipment, the 30tph jaw crusher often stands out thanks to its balance of performance and cost. Choosing the right jaw crusher for sale affects profitability and operational efficiency—making your equipment choice a…