Email: [email protected]

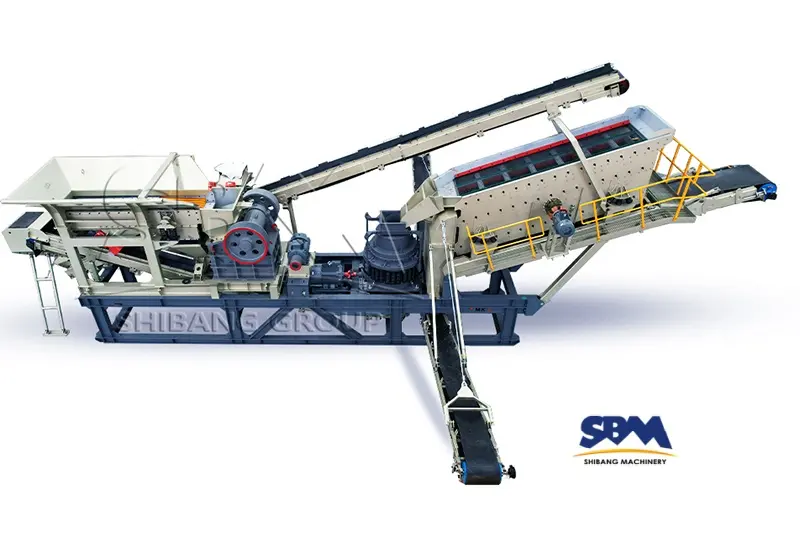

What Is Universal Jaw Crusher?

Universal jaw crushers are known for their deep crushing chambers that provide a positive, non- rebounding nip for faster throughput and increased reduction ratio. They are commonly used in various industries, including mining, quarrying, and recycling.

[icon name=”arrow-right” prefix=”fas”] Key features and characteristics of universal jaw crusher

- Robust Construction: Universal jaw crushers are typically built with heavy-duty steel frames to ensure durability and long service life. They are designed to handle high-capacity crushing operations and withstand heavy loads.

- Deep Crushing Chambers: Universal jaw crushers have deep crushing chambers that allow the material to be efficiently crushed and reduced in size. The deep crushing chamber design helps in achieving a higher reduction ratio and better particle shape.

- Adjustable Discharge Setting: Universal jaw crushers typically have a hydraulically adjustable discharge setting, which allows for precise control over the final product size. This feature enables the crusher to be optimized for different applications and materials.

- Aggressive Nip Angle: the jaw crusher has an aggressive nip angle, which refers to the angle between the fixed and movable jaw plates. The aggressive nip angle ensures strong gripping and efficient crushing of the material.

- Easy Maintenance: Universal jaw crushers are designed for easy maintenance. They often feature a removable pitman and side plates, making it convenient to access and replace wear parts when needed.

- Versatility: Universal jaw crushers are suitable for a wide range of applications. They can handle various materials, including hard and abrasive rocks, ores, and recycled concrete. They are commonly used for primary crushing but can also be used for secondary and tertiary crushing depending on the specific application.

- Optional Features: Universal jaw crushers may offer optional features such as hydraulic toggle adjustment, automatic lubrication systems, and safety devices to enhance the operational efficiency and safety of the crusher.

[icon name=”arrow-right” prefix=”fas”] What are the typical applications of universal jaw crusher?

- Mining: Universal jaw crushers are widely used in the mining industry for primary crushing of various types of minerals and rocks. They can handle hard and abrasive materials, such as granite, basalt, and iron ore.

- Quarrying: Universal jaw crushers are commonly employed in quarrying operations to process various types of rock and stone. They can efficiently crush materials extracted from quarries, including limestone, sandstone, and gravel.

- Recycling: Universal jaw crushers are suitable for recycling applications where the objective is to process construction and demolition waste into reusable aggregates. They can effectively crush and reduce concrete, asphalt, and other construction materials.

- Construction: Universal jaw crushers are utilized in construction projects for crushing materials required for infrastructure development. They can be used to process materials for road construction, building foundations, and other construction purposes.

- Aggregate Production: Universal jaw crushers are used in aggregate production plants to crush and shape materials for the production of high-quality aggregates used in concrete, asphalt, and other construction applications.

- Demolition: Universal jaw crushers can be employed in demolition projects to process and crush concrete structures, including walls, pillars, and foundations.

- Cement Industry: Universal jaw crushers are sometimes used in the cement industry for primary crushing of raw materials, such as limestone, shale, and clay.

- Railway Ballast: The jaw crushers can be used to crush and shape materials for the production of railway ballast, which is used as a foundation for railway tracks.

[icon name=”arrow-right” prefix=”fas”] Can universal jaw crushers handle different types of materials?

Yes, Universal jaw crushers are designed to handle a wide range of materials, including various types of rocks, minerals, and construction materials. They are known for their robust construction and versatile nature, allowing them to effectively crush different materials with varying characteristics.

The jaw crushers can handle materials with different hardness levels, from soft to extremely hard.

- Hard and Abrasive Rocks: Granite, basalt, quartzite, and gneiss.

- Ores: Iron ore, copper ore, gold ore, and silver ore.

- Construction and Demolition Waste: Concrete, asphalt, bricks, and rubble.

- Limestone and Sandstone: Limestone and sandstone, commonly used in construction and aggregate production.

- Gravel and Sand: Coarse gravel, fine gravel, and natural or manufactured sand.

- Recycled Materials: Recycled concrete, asphalt, and other construction and demolition waste materials.

Headquaters Office

Whatsapp:+8615225176731

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Website: https://www.mill-sbm.com/

Headquaters Office

Whatsapp:+8615225176731

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Website: https://www.mill-sbm.com/