E-mail: [email protected]

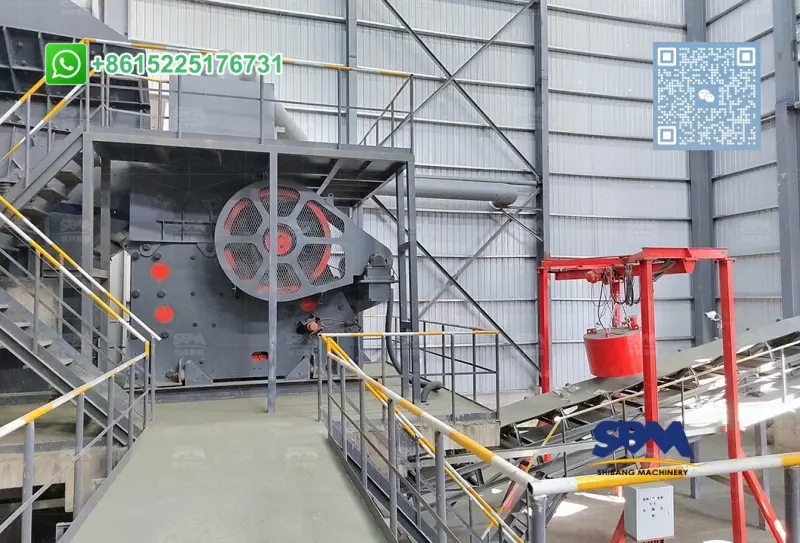

Impact Crusher avec 300 TPH pour les grands projets

Lorsque les géants miniers font face à des montagnes de minerai de fer ou de démolitions urbaines, génèrent des avalanches en béton, 300 TPH Impact Crusher apparaît comme des titans de transformation des matériaux. Au-delà des spécifications de base, nous analysons comment ces bêtes industrielles ont conquis les mines de cuivre chiliennes et les sites de démolition norvégiens, révélant des hacks de maintenance qui ont augmenté le débit d'une exploitation sidérurgique sud-africaine de 18% dernier trimestre.

Pourquoi les grands projets exigent des solutions de concassage de grande capacité?

Les projets d’infrastructures et miniers modernes nécessitent des équipements à la hauteur de leur ambition. Le concasseur à percussion avec 300 La capacité TPH a changé la donne pour les entrepreneurs en charge de la manutention:

- Construction d'autoroutes dans les régions montagneuses

- Traitement des matériaux en vrac pour les opérations minières

- Un réaménagement urbain avec des exigences concrètes en matière de recyclage

Un projet récent en Australie occidentale l'a démontré lorsqu'un Concasseur à percussion PF traité 287 TPH du minerai de fer constamment supérieur 18 mois, réduisant les temps d'arrêt de 40% par rapport aux modèles précédents.

Histoires de réussite mondiales: 300 Concasseurs TPH en action

Amélioration de la carrière de granit canadien

Une entreprise québécoise a remplacé leurs appareils vieillissants concasseur de roches avec un 300 Modèle d’impact TPH, réalisation:

- 22% production plus rapide de matériaux de base pour les routes

- Possibilité de traiter des blocs de granit de 2,8 m³

- Consommation d'énergie réduite grâce à une conception de rotor optimisée

Initiative norvégienne de recyclage du béton

Le mandat de construction verte d’Oslo a vu une concasseur à béton avec 300 Capacité TPH déployée sur 7 chantiers de démolition:

- Recyclé 1.2 millions de tonnes de béton dans 10 mois

- Produit un granulat uniforme de 20 à 40 mm pour les nouvelles fondations

- Intégré aux systèmes de broyeur de scories existants pour la récupération des métaux

Excellence en ingénierie: Qu'est-ce qui fait fonctionner ces concasseurs

Le 300 Le concasseur à percussion TPH brille:

- Système de réglage hydraulique permettant des changements rapides de taille de sortie

- Plaques d'impact à plusieurs étages qui traitent tout, du calcaire tendre au broyeur de marbre dur applications

- Surveillance intelligente prédisant le remplacement des pièces d'usure (Par exemple, barres de soufflage à 85% porter)

Une mine de cuivre chilienne signalée 92% disponibilité pendant les heures de pointe en utilisant ces fonctionnalités pendant le traitement matières premières de minerai avec 12-14% teneur en humidité.

Une polyvalence au-delà des attentes

Ces puissances ne se limitent pas aux rôles traditionnels:

- Une usine allemande les utilise comme concasseur principal de roches pour le basalte volcanique

- Les opérations sud-africaines les associent à broyeur de scories unités pour déchets de fusion de platine

- Les champs pétrolifères du Texas écrasent les agrégats des plates-formes de forage tout en effectuant des tâches occasionnelles de broyage de béton

Pérenniser votre activité

Lors de la sélection d'un concasseur à percussion PF ou d'un modèle similaire:

- Vérifier la compatibilité avec les équipements auxiliaires

- Exigez des essais avec vos matériaux spécifiques

- Vérifiez le support du marché secondaire pour les pièces d'usure

Le 300 Le seuil TPH représente bien plus que de simples chiffres de débit : il s'agit de créer une flexibilité opérationnelle. Comme on le voit dans un projet d'infrastructure malaisien, cette capacité a permis une alimentation simultanée à partir de trois points de chargement tout en maintenant la cohérence du produit final pour la construction du pont.