ईमेल: [email protected]

जबडा क्रशरचे भाग काय आहेत?

जबडा क्रशर हे खाणकामासाठी परिपूर्ण वर्कहॉर्स आहेत, एकूण, आणि बांधकाम उद्योग. प्रमुख जबडा क्रशर पार्ट्स समजून घेतल्याने खरेदीदारांना स्मार्ट गुंतवणूक करण्यात मदत होते, अपटाइम वाढवा, खर्च नियंत्रित करा, आणि देखभाल कार्ये ऑप्टिमाइझ करा. चला प्रत्येक मुख्य भाग खंडित करूया, खरेदीदारांसाठी व्यावहारिक उदाहरणांसह.

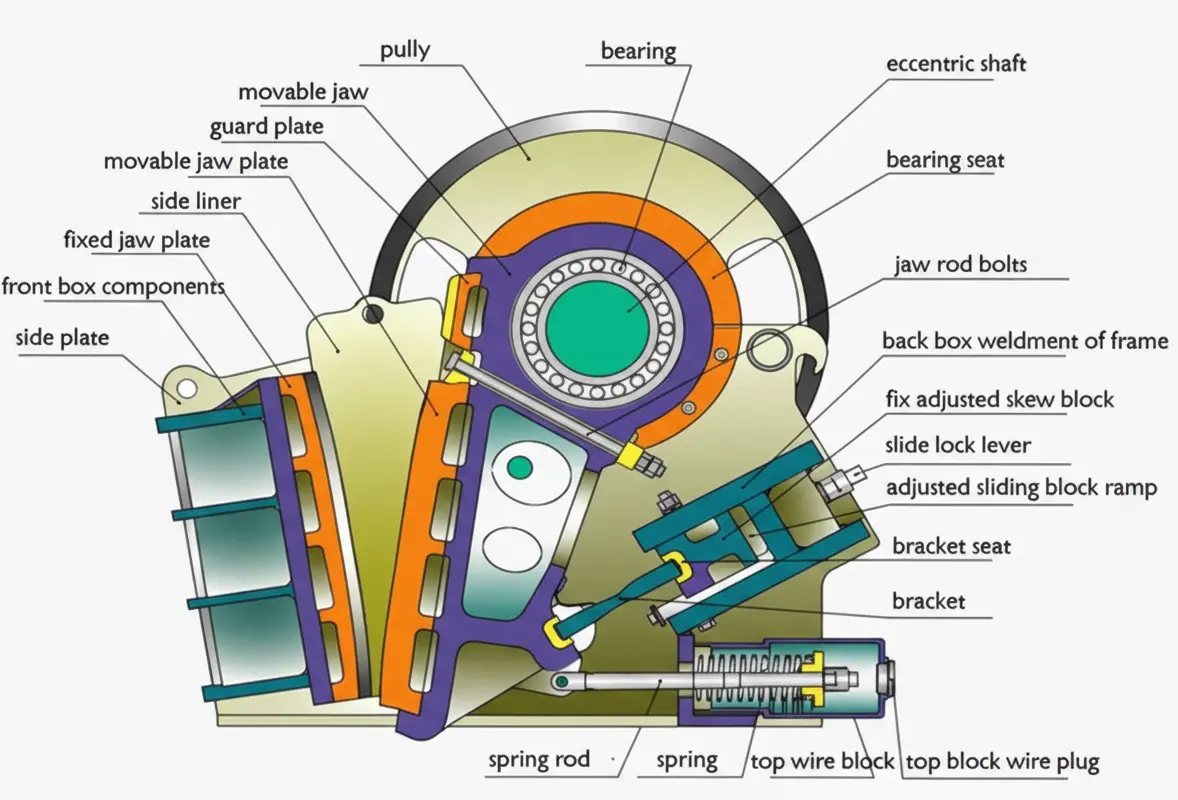

जबडा क्रशर पार्ट्स विहंगावलोकन

जबडा क्रशरमध्ये भिन्न स्थाने आणि कार्यांसह अनेक मुख्य भाग असतात. प्रत्येक भागामध्ये खोलवर जाण्यापूर्वी येथे एक द्रुत सारांश सारणी आहे.

| भागाचे नाव | स्थान | भूमिका/कार्य | मुख्य साहित्य | किंमत श्रेणी |

|---|---|---|---|---|

| जबडा प्लेट | निश्चित & हलणारे जबडे | क्रशिंग पृष्ठभाग | मँगनीज स्टील | $200-$3,000/पीसी |

| गाल प्लेट | जबड्याच्या चेंबरच्या बाजू | बाजूच्या भिंती संरक्षित करा | मँगनीज स्टील, मिश्रधातू | $100– $1,000/pc |

| विक्षिप्त शाफ्ट | केंद्र, लांबीच्या दिशेने चालते | जबड्याची हालचाल चालवते | उच्च-कार्बन स्टील | $350-$2,500/pc |

| क्रशर बॉडी/फ्रेम | संपूर्ण बेस | स्ट्रक्चरल समर्थन | कास्ट लोह, स्टील, मिश्रधातू | $1,000-$12,000 |

| फ्लायव्हील | बाजू, बाहेर चेंबर | जबड्याच्या हालचालींना शक्ती देते | कास्ट लोह, स्टील | $500-$3,000/पीसी |

| टॉगल प्लेट | जबडा प्लेट्स अंतर्गत | सुरक्षा & जबडा बल हस्तांतरण | पोलाद, मिश्रधातू | $180– $800/पीसी |

| पिटमॅन/रॉकर | जबडा/शाफ्ट जोडतो | जबडा हलवतो, शक्ती प्रसारित करते | पोलाद | $400– $2,000/pc |

| बेअरिंग्ज | शाफ्ट / जबडा समर्थन | रोटेशन/हालचाल सक्षम करते | मिश्रधातूचे स्टील, बीयरिंग्ज | $120–$1,200/pc |

| गार्ड प्लेट | प्लेट्सच्या खाली | हलणाऱ्या जबड्याच्या पायाचे रक्षण करते | पोलाद, मिश्रधातू | $80– $400/पीसी |

| समायोजन ब्लॉक | डिस्चार्ज वेळी | आउटपुट आकार नियंत्रित करते | पोलाद, मिश्रधातू | $150– $900/पीसी |

| स्प्रिंग/टेन्शन रॉड | टॉगल अंतर्गत | टॉगल प्रेशर राखते | मिश्रधातूचे स्टील | $60– $400/पीसी |

| हायड्रोलिक प्रणाली | आधुनिक क्रशर | CSS/सुरक्षा वैशिष्ट्ये समायोजित करते | पोलाद, हायड्रॉलिक भाग | $1,000– $6,000/किट |

| कन्वेयर बेल्ट | आउटपुट विभाग | साहित्य वाहतूक | रबर/फायबर स्टील | $300– $2,000/प्रवेश |

| फीड हॉपर | प्रवेश | येणारे साहित्य ठेवते | पोलाद, मिश्रधातू | $400-$2,500/pc |

| मोटार | पॉवर विभाग | चळवळ चालवते | इलेक्ट्रिक/गॅस मोटर | $600– $5,000/युनिट |

जबडा प्लेट्स

स्थान आणि कार्य

जबड्याच्या प्लेट्स हा जबडा क्रशरचा सर्वात महत्वाचा भाग असतो. एक प्लेट स्थिर राहते आणि शरीरावर स्थिर असते. दुसरी प्लेट हलते, आणि ते पिटमॅनला जोडलेले आहे, शाफ्टला धन्यवाद मागे मागे फिरणे. जेव्हा खडक किंवा इतर साहित्य आत जाते, प्लेट्स एकत्र दाबतात आणि त्या फोडतात.

साहित्य आणि स्थान

बहुतेक जबड्याच्या प्लेट्स कडक मँगनीज स्टील किंवा धातूंच्या मिश्रणापासून बनविल्या जातात. आपण त्यांना मशीनच्या आत मुख्य क्रशिंग पृष्ठभागावर शोधू शकता. काही जबड्याच्या प्लेट्समध्ये विशेष सामग्री वापरली जाते जी जास्त काळ टिकते.

किंमत आणि उपलब्धता

जबड्याच्या प्लेट्सची किंमत निर्मात्यावर अवलंबून असते, ते किती जाड आहेत, त्यात किती मँगनीज असतात, आणि आकार. सहसा, प्रत्येक प्लेटची किंमत आहे $200 करण्यासाठी $3,000, आणि अधिक प्रगत डिझाईन्स अधिक महाग आहेत.

आतील टीप

तुमच्या जबडयाच्या प्लेट्स वारंवार तपासल्याने आणि त्या योग्य वेळी बदलल्याने तुमच्या क्रशरला चांगले काम करण्यात आणि दीर्घकाळ टिकण्यास मदत होते.

गाल प्लेट्स

स्थान आणि कार्य

क्रशिंग चेंबरच्या बाजूला गालाच्या प्लेट्स बोल्ट केल्या आहेत, खडक आत सरकत असताना यंत्राच्या भिंतींचे घर्षण होण्यापासून संरक्षण करणे

साहित्य आणि स्थान

पोशाख-प्रतिरोधक मँगनीज स्टील किंवा विशेष मिश्र धातु पासून उत्पादित, चीक प्लेट्स मशीनचे आयुष्य वाढवतात आणि फ्रेमचे नुकसान कमी करतात.

किंमत आणि बाजार

गाल प्लेट्सची किंमत $100 करण्यासाठी $1,000 प्रत्येक, आकार आणि मिश्र धातुच्या ग्रेडवर अवलंबून

द्रुत टीप

उत्कृष्ट कामगिरीसाठी आणि परिधान करण्यासाठी गालाच्या प्लेट्स जॉ प्लेट्ससह बदला

विक्षिप्त शाफ्ट

स्थान आणि कार्य

पिटमॅनमधून धावत आहे, विक्षिप्त शाफ्ट जंगम जबड्याचे दोलन चालवते. हे रोटेशनल एनर्जीचे रूपांतर रेषीय हालचालीमध्ये करते, खडक आणि धातूचा चुरा करणारी "च्युइंग" गती तयार करणे

साहित्य आणि डिझाइन

ताकद आणि टॉर्क प्रतिरोधासाठी उच्च-कार्बन किंवा मिश्र धातुच्या स्टीलपासून तयार केलेले. शाफ्ट एंड फ्लायव्हील आणि मोटरला जोडतो.

किंमत

बाजारातील किंमत $350-$2,500 पर्यंत आहे, मुख्यत्वे शाफ्ट व्यास आणि स्टील ग्रेडवर आधारित

क्रशर बॉडी/फ्रेम

स्थान आणि उद्देश

हा पायाभूत कवच आहे—जॉ क्रशरच्या इतर सर्व भागांना आधार देतो आणि क्रशिंग प्रेशर सहन करतो.. प्रत्येक कार्यरत घटकाभोवती स्थित.

साहित्य प्रकार

कास्ट लोहापासून फ्रेम्स बांधल्या जातात, कार्बन स्टील, मिश्र धातु स्टील, किंवा अत्यंत पोशाख-प्रतिरोधक जड स्टील प्लेट्स, अनेकदा संमिश्र मजबुतीकरणासह

किंमत संकेत

क्रशर फ्रेम महाग आहेत, पासून यावरील $1,000 करण्यासाठी $12,000 आकारावर अवलंबून. म्हणूनच स्टील ग्रेड आणि डिझाइन खरेदीदारांसाठी खूप महत्त्वाचे आहे.

फ्लायव्हील

स्थान आणि उद्देश

फ्लायव्हील विक्षिप्त शाफ्टच्या बाहेरील बाजूस जोडलेले आहे. ते फिरणारी ऊर्जा साठवते, जबडा सुरळीत चालण्यास मदत करणे आणि क्रशर स्थिर गतीने चालू ठेवणे.

साहित्य वापरले

सहसा कास्ट लोह किंवा बनावट स्टील, ऑपरेशनल स्थिरतेसाठी अचूक संतुलनासह.

बाजारभाव

फ्लायव्हील्सची किंमत साधारणपणे प्रत्येकी $500–$3,000 असते, व्यास आणि सामग्रीच्या गुणवत्तेवर अवलंबून

टॉगल प्लेट

कार्य आणि स्थान

जबड्याच्या प्लेट्सच्या खाली सुरक्षा यंत्रणा म्हणून काम करणे, प्लेट्स ट्रान्सफर फोर्स टॉगल करा आणि अत्यंत तणावाखाली खंडित करा, अधिक महाग नुकसान रोखणे.

साहित्य निवड

मुख्य निवडी म्हणजे मिश्र धातु स्टील्स आणि अचूक-कास्ट धातू.

बाजारभाव

टॉगल प्लेट्स पासून बदलू शकतात $180 ते $800/तुकडा, सामग्री आणि डिझाइनची जटिलता प्रतिबिंबित करते.

पिटमॅन (रॉकर)

स्थान आणि कार्य

पिटमॅन, रॉकर देखील म्हणतात, हलणारा जबडा शाफ्टशी जोडतो आणि सामग्री क्रश करण्यासाठी आवश्यक असलेल्या शक्तीवर जातो. हे मजबूत दाब हाताळते, त्यामुळे ते कठीण आणि चांगले तयार करणे आवश्यक आहे.

साहित्य

मुख्यत्वे प्रीमियम मिश्र धातु किंवा कार्बन स्टील पासून उत्पादित.

बाजारभाव

वस्तुमान आणि मिश्रधातूवर अवलंबून $400–$2,000 पर्यंत श्रेणी

खरेदीदाराची टीप

पिटमॅनचे वाढलेले वजन क्रशिंग फोर्सला चालना देऊ शकते, परंतु किंमत आणि इनपुट पॉवर मागणी देखील वाढवते

बेअरिंग्ज

स्थान आणि कार्य

बियरिंग्ज विक्षिप्त शाफ्ट आणि जंगम जबड्याला आधार देतात, गुळगुळीत रोटेशन प्रदान करणे आणि घर्षण कमी करणे. उच्च-गुणवत्तेचे बेअरिंग म्हणजे उपकरणांचे दीर्घ आयुष्य

साहित्य निवडी

आदर्श बियरिंग्ज कठोर मिश्र धातुच्या स्टीलपासून बनविल्या जातात, धूळ आणि ओलावा संरक्षणासाठी प्रगत सीलसह.

किंमत ट्रेंड

अपेक्षा $120 करण्यासाठी $1,000+ प्रति बेअरिंग, व्यासाने मोठ्या प्रमाणावर प्रभावित, ब्रँड, आणि सील तंत्रज्ञान.

गार्ड प्लेट्स

फंक्शन आणि प्लेसमेंट

हलवता येण्याजोगा जबडा पाया खाली आरोहित, गार्ड प्लेट मोठ्या ढिगाऱ्याला गंभीर हलणारे भाग अडकण्यापासून प्रतिबंधित करते

साहित्य निवड

सामान्यतः स्टील किंवा मिश्र धातु, काहीवेळा जोडलेल्या पोशाख प्रतिकारासाठी मजबूत केले जाते.

किंमत श्रेणी

$80- $400 प्रति तुकडा.

समायोजन ब्लॉक/सेटिंग सिस्टम

स्थान आणि उद्देश

समायोजन ब्लॉक जबडा किती अंतरावर आहे हे नियंत्रित करते, जे बाहेर येणा-या सामग्रीचा आकार बदलतो. साध्या ऍडजस्टमेंट सिस्टममुळे क्रशरचे निराकरण करणे किंवा सेट करणे अधिक जलद आणि सोपे होते.

साहित्य

सहसा स्टील, कधीकधी मिश्रधातू-प्रबलित.

किंमत

$150– $900 प्रति समायोजन ब्लॉक, हायड्रॉलिक किंवा स्वयंचलित असल्यास उच्च.

स्प्रिंग्स आणि टेंशन रॉड्स

स्थान आणि कार्य

टॉगल प्लेट्सच्या खाली किंवा बाजूला स्थित, स्प्रिंग्ज योग्य जबड्याचा ताण राखतात आणि टॉगल सुरक्षा कृतीला समर्थन देतात

साहित्य

मिश्र धातु किंवा कठोर कार्बन स्टील.

ठराविक बाजारभाव

पासून श्रेणी $60 करण्यासाठी $400 प्रति असेंब्ली.

हायड्रोलिक प्रणाली (आधुनिक क्रशर)

स्थान आणि कार्य

नवीन पिढ्यांमध्ये CSS ऍडजस्टमेंटसाठी हायड्रॉलिक सिस्टीम वैशिष्ट्यीकृत आहेत, ओव्हरलोड संरक्षण, आणि जॅम क्लिअरिंग—टॉगल मेकॅनिझमजवळ स्थित

साहित्य व्याप्ती

स्टील हायड्रॉलिक सिलेंडर, ओळी, आणि इलेक्ट्रॉनिक नियंत्रणे.

किंमत अंदाज

हायड्रॉलिक किट $1,000-$6,000 चालतात, व्याप्ती आणि ब्रँडवर अवलंबून.

कन्व्हेयर बेल्ट आणि फीड हॉपर

स्थान आणि कार्य

फीड हॉपर्स एंट्रीवर राहतात, क्रशर मध्ये कच्चा माल मार्गदर्शक. कन्व्हेयर बेल्ट आउटपुट बाजूला बसतात, प्रक्रिया केलेले साहित्य पुढे हलवणे

साहित्य आणि किंमत

हॉपर हे जड स्टील किंवा मिश्र धातु आहेत, $400-$2,500. कन्व्हेयर बेल्टची श्रेणी प्रति ओळ $300–$2,000 आहे.

मोटर्स

फंक्शन आणि प्लेसमेंट

मोटर शाफ्ट आणि फ्लायव्हीलशी जोडलेली आहे. हे क्रशर हलविण्यासाठी आवश्यक शक्ती देते.

प्रकार/साहित्य

इलेक्ट्रिक किंवा गॅसवर चालणारे, तांबे विंडिंग वापरणे, कास्ट हाऊसिंग.

किंमत

HP आणि ब्रँडवर अवलंबून मोटर्सची किंमत प्रति युनिट $600–$5,000 आहे

जबडा क्रशर भाग साहित्य तुलना

| भाग | मुख्य साहित्य | सामर्थ्य | दीर्घायुष्य |

|---|---|---|---|

| जबडा प्लेट | मँगनीज स्टील | ओरखडा, प्रभाव प्रतिकार | उच्च |

| गाल प्लेट | मँगनीज स्टील, मिश्रधातू | परिधान करा, शॉक संरक्षण | उच्च |

| फ्रेम/बॉडी | कास्ट लोह, स्टील, मिश्रधातू | विकृती, ताण प्रतिकार | खूप उच्च |

| शाफ्ट | उच्च-कार्बन स्टील | वाकणे, टॉर्क प्रतिकार | उच्च |

| फ्लायव्हील | कास्ट लोह, स्टील | स्थिरता, जडत्व | उच्च |

| बेअरिंग्ज | मिश्रधातूचे स्टील, सीलबंद | घर्षण, प्रतिकार परिधान करा | उच्च |

| टॉगल प्लेट | पोलाद, precision-cast | ओव्हरलोड संरक्षण | मध्यम-उच्च |

जबडा क्रशर किंमती & मूल्य घटक

किती जबडा क्रशर आणि त्यांच्या भागांची किंमत अनेक गोष्टींमुळे बदलू शकते:

- वापरलेल्या साहित्याचा प्रकार (चांगले स्टील, धातूचे मिश्रण, किंवा विशेष भाग किमती वाढवतील).

- ब्रँड (प्रसिद्ध ब्रँडची किंमत सहसा जास्त असते, परंतु अनेकदा चांगली हमी आणि ग्राहक सेवा देतात).

- क्रशर किती आकार आणि किती हाताळू शकतो (मोठ्या मशीन्स किंवा ज्या प्रत्येक तासाला अधिक क्रश करू शकतात त्या सहसा किमतीत असतात).

- अतिरिक्त वैशिष्ट्ये (हायड्रॉलिक सिस्टम सारख्या गोष्टी, स्वयंचलित तेल घालणे, किंवा विशेष फीडर खर्चात भर घालू शकतात).

- बाजार (मागणी सारख्या गोष्टी, स्थान, वितरण खर्च, आणि तुम्ही खरेदी केल्यानंतर मदतीमुळे किंमती वाढू शकतात किंवा कमी होतात).

उदाहरण तपशील सारणी

| मॉडेल | कमाल फीड आकार (मिमी) | डिस्चार्ज श्रेणी (मिमी) | फीड उघडणे (मिमी) | शक्ती (kw) | क्षमता (टी/ता) | वजन (t) |

|---|---|---|---|---|---|---|

| PE-250×400 | 210 | 20-60 | 250×400 | 15 | 5-२० | 2.8 |

| PE-600×900 | 500 | 65-१६० | 600×900 | 55-75 | 70-150 | 15.5 |

| PE-1200×1500 | 1020 | 150–300 | 1200×1500 | 160-२२० | 400-1000 | 100.9 |

देखभाल & दीर्घायुष्य टिपा

आपल्या जबड्याच्या प्लेट्स तपासा, बीयरिंग्ज, प्लेट्स टॉगल करा, बेल्ट, आणि तुमच्या क्रशरला जास्त काळ टिकण्यास मदत करण्यासाठी दररोज किंवा आठवड्यात रक्षक. बेअरिंगमध्ये तेल घाला, क्रॅक किंवा जीर्ण भाग पहा, आणि जबड्याच्या प्लेट्स बरोबर रांगेत आहेत याची खात्री करा. नियमित तपासणी चेकलिस्ट चालवा - बहुतेक अपयश दुर्लक्षित झाल्यामुळे होतात जबडा क्रशरची देखभाल.

खरेदीदाराची व्यावहारिक चेकलिस्ट

- जास्त काळ टिकण्यासाठी योग्य प्रकारचे मँगनीज वापरून बनवलेल्या जबड्याच्या प्लेट्स आणि गालाच्या प्लेट्स निवडा.

- किंमती पाहताना, उपलब्ध स्पेअर पार्ट्सबद्दल विचार करण्याचे लक्षात ठेवा, हमी, आणि विक्रीनंतरची मदत.

- SBMCchina सारख्या विश्वसनीय वेबसाइटवर तुम्ही पाहता ते ब्रँड निवडा—त्यांच्याकडे चांगली गुणवत्ता आणि वास्तविक तांत्रिक तपशील आहेत.

- हायड्रॉलिक सिस्टीम्स सारखे चांगले साहित्य आणि आधुनिक भाग वापरण्यासाठी थोडा जास्त खर्च येतो, परंतु यामुळे दीर्घकाळात पैशांची बचत होते आणि क्रशरचे निराकरण करणे सोपे होते.

- भाग क्रमांक आणि बदलांची नोंद ठेवा, जेणेकरून क्रशरने काम करणे थांबवल्यास तुम्ही गोष्टी जलद निराकरण करू शकता.

निष्कर्ष

नामें जाण, भूमिका, साहित्य, आणि किंमत श्रेणी जबडा क्रशर भाग खरेदीदारांना हुशार निवड करण्यात मदत करते, चांगले मूल्य मिळवा, आणि उपकरणे समस्या टाळा. विश्वसनीय कंपन्यांकडून खरेदी करा, चांगल्या देखभालीवर लक्ष केंद्रित करा, आणि भाग तपशील वारंवार तपासा. तुम्हाला योग्य क्रशर मॉडेल निवडण्याबाबत सल्ला हवा असल्यास, तपशील, किंवा कोट, फक्त विचारा-मग तुम्ही आत्मविश्वासाने खरेदी करू शकता.