E-mail: [email protected]

Triturador de granito móvel vs planta estacionária: O que é melhor para o seu projeto?

When you plan a granite crushing project, one of the first decisions is whether to invest in a stationary plant vs a mobile granite crusher. Both can process hard, granito abrasivo, but they suit very different working styles, contracts, and budgets. Choosing the wrong type leads to higher cost per ton, wasted capacity, or poor flexibility.

This guide focuses on the real need behind the search for “mobile granite crusher”: not just what the machine is, but when it actually makes sense, how to configure it, and how to avoid common mistakes when comparing mobile and stationary options.

When Does a Mobile Granite Crusher Make Sense?

Trituradores móveis are not only about “cool tracks” or convenience—they are a business tool. They work best when at least one of the following is true:

- Short-term or moving projects

- Construção de estradas, wind farm bases, or small granite outcrops where the worksite changes frequently.

- Scattered deposits

- Several small granite pits that are too far apart to feed one central stationary plant economically.

- Limited or uncertain project life

- You want to keep flexibility because you may move to another region or change material after a few years.

- On-site crushing for clients

- As a contractor, you bring the crusher to the client’s granite source instead of transporting rock to a fixed plant.

If you have a large, long-life granite quarry and stable demand, a stationary plant usually wins on cost per ton. If you must move often or work on many sites, a mobile granite crusher can be the better choice despite higher unit cost.

Mobile vs Stationary Granite Crushing – Key Differences

1. Investment and Operating Cost

- Planta estacionária

- Higher upfront investment in civil works and fixed structures.

- Lower long-term cost per ton, especially above 200–300 tph.

- Mobile granite crusher

- Lower civil cost and faster setup; you mainly pay for the mobile units themselves.

- Higher operating costs per ton (combustível, vestir, smaller capacity) but more flexibility.

2. Capacity and Product Range

- Stationary

- Móvel

- Typical single-line capacities range about 50–300 tph.

- Enough for many infrastructure projects and regional markets, but not ideal for very large, long-term granite quarries.

3. Flexibility and Redeployment

- Stationary

- Best if the granite source and demand location are stable for many years.

- Relocation is expensive and slow.

- Móvel

- Can be moved within days or even hours between sites.

- Allows you to follow the face in the pit, reducing truck haul distance.

Typical Mobile Granite Crusher Configurations

1. Mobile Jaw + Mobile Cone for Granite

Configurar:

- Mobile primary jaw crusher (trumck ou wheel-mounted)

- Mobile cone crusher para britagem secundária

- Mobile screen (often combined with cone or separate)

Melhor para:

- Hard granite with required capacity around 100–300 tph.

- Projects needing good balance between flexibility and quality aggregates.

Prós:

- Compression crushing in both stages, more suitable for abrasive granite.

- You can park the train closer to the face and move as the pit deepens.

Contras:

- Higher total fuel and wear cost vs a similar stationary line.

- More complex to operate and coordinate when moving frequently.

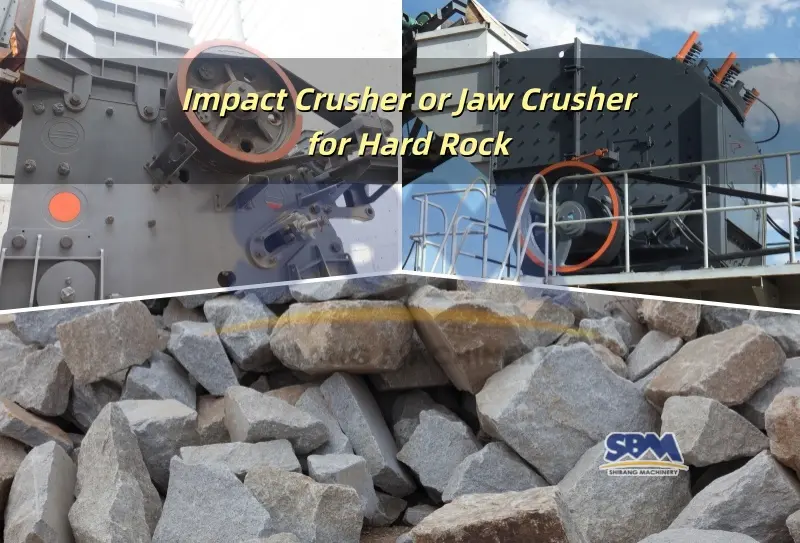

2. Mobile Jaw + Mobile Impact for Granite (Selective Use)

Configurar:

- Mobile jaw as primary.

- Mobile impact crusher as secondary/shaping.

Melhor para:

- Granite mixed with softer rock or recycled material.

- Cases where product shape is more important than liner life.

Prós:

- Very good particle shape for concrete and asphalt.

- Can produce value-added smaller sizes in a compact footprint.

Contras:

- Wear on impact blow bars and liners can be very high in pure hard granite.

- Usually works best when impact handles pre-crushed, well-controlled feed.

3. Single Mobile Cone (Secondary Only)

Configurar:

- Stationary jaw at the main quarry + mobile cone used on remote stockpiles or satellite pits.

Melhor para:

- Larger producers who already have a stationary primary, but need mobile secondary capacity in specific locations.

Prós:

- Re-uses existing stationary jaw investment.

- Adds flexible capacity where and when needed.

Contras:

- More coordination and logistics required to balance main and satellite production.

Choosing Between Mobile and Stationary for Granite – Decision Checklist

- How long will you work on this granite source?

- More than 8–10 years with large reserves → stationary is usually better.

- Shorter or uncertain life → mobile gains importance.

- How many sites do you plan to operate?

- One large quarry → stationary.

- Multiple small pits or contract sites → mobile or hybrid.

- What is your target capacity?

- Acima 300 tph continuous → stationary is generally more economical.

- 50–300 tph range → mobile solutions are realistic.

- How far is the face from the nearest power and infrastructure?

- Close and easy access → stationary.

- Remote or difficult terrain → mobile may save haulage and civil cost.

- What is more important right now: lowest cost per ton, or maximum flexibility?

- Lowest cost per ton → stationary.

- Flexibility and contract work → mobile.

The Questions When Buying a Mobile Granite Crusher – and How to Avoid Them

- Point 1: Buying a mobile crusher designed for softer rock

- Some mobile units are optimized for limestone or recycling; using them on hard granite leads to poor performance and fast wear.

- Solução: insist on proven granite references and check wear part design for hard, abrasive material.

- Point 2: Underestimating logistics and permits

- Frequent moves mean permits, road transport, and extra planning.

- Solução: calculate not only the crushing cost, but also moving and setup time.

- Point 3: Running a mobile crusher like a stationary plant

- Parking in one place for years often means you would have been better with a fixed plant.

- Solução: be honest about how often you will really move; choose stationary or hybrid if movement is rare.

- Point 4: Poor local after-sales and parts support

- For mobile units, downtime on the road can be more painful than in a permanent plant.

- Solução: check spare parts availability, service network, and remote support before buying.

FAQs About Mobile Granite Crushers

In smaller to medium ranges (around 50–300 tph), mobile granite crushers can reach capacities similar to stationary setups. For very high capacities above 300–400 tph, stationary plants are usually more efficient and economical.

Typically yes, on a cost-per-ton basis, due to higher fuel consumption, smaller scale, and sometimes higher wear. No entanto, for short-term or multi-site projects, the flexibility and reduced hauling can still make mobile solutions more profitable overall.

Many companies do this: they begin with a mobile unit to test the market and generate early cash flow, then invest in a stationary plant once reserves, demand, and permits are stable. If planned from the beginning, some mobile units can even be reused as backup or satellite crushers after the stationary line is built.