Email: [email protected]

What is Stone Crusher

Imagine modern infrastructure projects without stone crusher (What is Stone Crusher): Preparation of basic building materials willtrapped in a manual process for weeks! In fact, This stone crushing machine isVital Industrial Tools—processing large rocks into gravel, pasir, or dust for construction, mining, and recycling materials.He is the spine who developed the road to the skyscrapers.

Types of Stone Crushers Explained

Various types of stone breaking machines are designed for different stages and materials:

- Jaw destroyer: Suitable for primary destruction of hard rocks such as granite or basalt. This tool works with two metal plates (jaw) which presses the material until it is destroyed. Sample: SBM's C6X Series with Capacity10–1,250 tph and material acceptance up to1,400 mm.

- Cone destroyer: Used for secondary/tertiary destruction. Using a rotating cone in a static basin, ideal for producing cube -shaped aggregates. SBM® HP100 ™ For example, able to perfect the final form of the product while saving energy.

- Impact Crusher: Destroying material via high -speed hammer blows (example: SBM’s CI5X for soft rocks like limestone).

- Hammer Crusher: Efficient for fragile materials such as coal or limestone, but the risk of producing too much dust and is not suitable for abrasive rocks.

How Stone Crushers Function?

Stone Crusher's way of work depends on the type, but the basic principle involvesMechanical breakdown through compression, impact, or friction:

- OnJaw destroyer, The material is pinched between two metal jaws, One of them moves back and forth eccentric.

- OnCone destroyer (like HP100), cone in spinning inside the outer basin. This movement creates a repeated destruction zone when the material drops downward.

- Security systems like a spring onCS Series Spring Cone Crusher protect the engine from overload by allowing foreign metals through the destruction space without damaging the machine.

Key Components in Crushing Machines

The main component of Stone Crusher determines its endurance and efficiency:

- Jaw Plates/Dies: Jaw plate in the jaw destroyer, Made of high manganese steel for abrasion resistance.

- Mantle & Concave: The cone part moves (mantle) and static basins (concave) pada cone crusher. On HP100, The design is optimized for the distribution of wear is equitable.

- Rotor & Hammers: Fast spinning shaft and hammer on impact/hammer crusher.

- Hydraulic system: Set discharge openings (for example on SBM C6X 160-130) and cleaning the cavity when clogged.

Selecting the Right Crusher for Your Needs

The selection of machines depends on three key factors:

- Material Input:

- Hard rock (granit, basalt) → jaw destroyer or cone crusher.

- Soft rock (kapur, coal) → Hammer Crusher or impact destroyer.

- Output Size:

- Rough grain (>50mm) → jaw destroyer.

- Fine aggregate (5–20mm) → cone crusher (like SBM HP100) or short-head cone crusher.

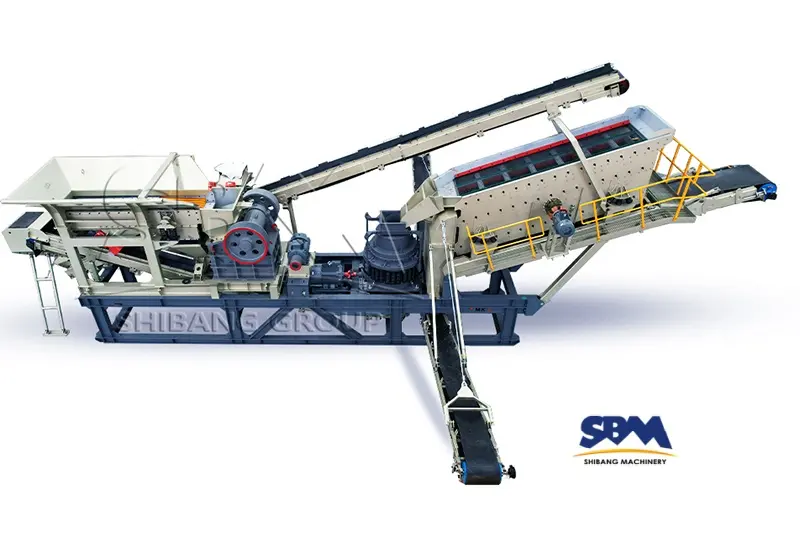

- Mobility: For the location of moving, usewheel-mounted crusher as can be installed in a truck or trailer.

💡Tips from members: For large mining operations, combination “jaw destroyer + cone destroyer + Sand Making Machine” produce high -quality aggregate with maximum efficiency. While for small projects, portable jaw destroyer Like Crazycrusher, it can even be operated manually in the field!

Maintenance and Safety Best Practices

Routine maintenance and safety procedures extend the life of the engine and protect the operator:

- Periodic lubrication: Lubrication System in Cone Crusher (Like Py Series) use a mixture of dry oil and water to prevent rock dust contamination.

- Replacement Wear Parts: Mantle, concave, or Jaw Plates must be examined every 500-1,000 operating hours.

- Operator safety:

- Always useeye protection, dust mask, and gloves when operating a crusher or cleaning debris.

- Automation systems such as SBM control the process from a distance, Reducing physical risk exposure.

Why Stone Crushers Are Indispensable?

Stone crusher is not just stone crusher machine—It isthe heart of the modern construction and mining industry. From the giant jaw crusher processing 1,000 TPH Volcanic Stone, until the precision cone crusher that forms a fine aggregate for concrete, Each type plays a unique role in the transformation of natural materials.

By understandingWhat is Stone Crusher, types, and selection criteria, You not only save operational costs but also ensure the smooth running of the project from the mine to the building!