Email: [email protected]

Construction Waste Crushing Process

The construction waste crushing process is now key for many projects. It helps contractors, mining firms, and builders cut costs. It also supports rules that protect the environment. At the same time, it turns site waste into useful raw material. In Latin America, many landfills are almost full. Transport costs for waste and new stone are also high. A good crushing plant can greatly improve project profit. When teams master this process, debris stops being a problem. It becomes recycled aggregate for roads, concrete, fill, and subbases. On-site crushing with mobile units cuts many truck trips. This lowers the carbon footprint from transport and quarry work.

What is the process for crushing and processing construction waste?

Construction and demolition waste is a mix of many site materials. It can contain concrete, bricks, blocks, asphalt, stones, and soil. It also includes steel bars, wood, plastic, and other site debris. For an efficient crushing process, sorting is very important. Workers must remove as many wrong materials as they can. This includes wood, plastics, plaster, and any risky waste. Sorting should happen before or during the treatment line.

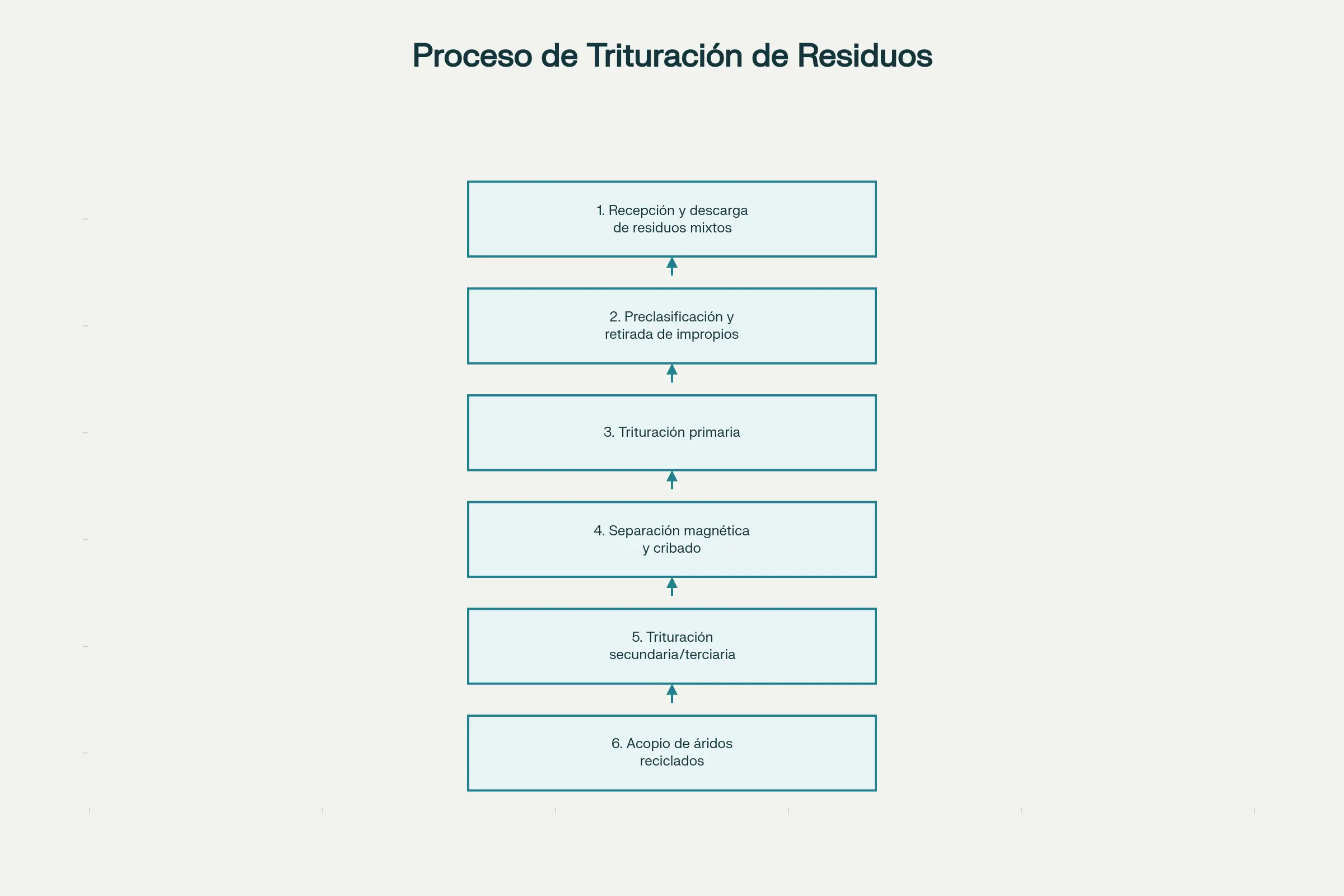

In general, the construction waste crushing process follows clear steps. First comes reception and then pre-classification of the material. Next, the waste goes through primary crushing and magnetic separation. After that, it is screened to sort different sizes. If needed, there is secondary or even tertiary crushing. Depending on volume and site layout, you can install a fixed plant. Another option is a mobile crushing plant that moves between sites.

What is the general process for crushing construction waste?

A typical construction waste crushing process flow includes several well-defined stages. Broadly speaking, the material enters as heterogeneous rubble and exits as size-sorted recycled aggregate, ready for reuse.

Typical stages:

- Reception and unloading of mixed construction waste.

- Pre-sorting and removal of contaminants (bulky metals, plastics, wood).

- Primary crushing (generally jaw or impact).

- Magnetic separation and screening.

- Secondary/tertiary crushing, if finer sizes are required.

- Stockpiling and loading of recycled aggregates for various uses.

Stage 1: Waste reception and logistics

The construction waste shredding process begins with the arrival of material from demolitions, renovations, or large infrastructure projects. Efficient logistics in the receiving area reduce downtime and prevent contamination of construction waste with garbage or other unwanted materials.

Practical recommendations:

- Define separate areas for clean construction waste (concrete and masonry only) and mixtures with a higher percentage of impurities.

- Monitor the weight and origin of each truck to ensure traceability and mass balance at the construction waste crushing plant.

Stage 2: Pre-classification and removal of unsuitable materials

Before crushing construction waste, it’s advisable to perform a manual or mechanical pre-sorting to remove problematic materials. This stage involves separating large metals, bulky plastics, wood, glass, and non-mineral waste that could damage the crusher or worsen the quality of the recycled aggregate.

The following can be used:

- Shovels and excavators with trained operators to remove large pieces.

- Inspection conveyors where operators sort out unsuitable materials.

- Vibrating pre-screens that separate fines and facilitate uniform feeding to the construction waste crusher.

Stage 3: Primary crushing of construction waste

Primary crushing of construction waste is typically carried out using jaw crushers or impact crushers, either stationary or mobile. The aim is to reduce large blocks of concrete, brick, and asphalt to an intermediate size that can pass through screening and, if required, a secondary crushing stage.

- Jaw crusher: robust, ideal for large concrete blocks and hard rubble; recommended as the first step in the construction waste crushing process when there are very bulky pieces.

- Impact crusher: very suitable for construction and demolition waste, produces well-shaped and high-quality recycled aggregates, especially in concrete and asphalt.

Stage 4: Magnetic separation and screening

After you crush the construction waste, you pass the material under a magnetic separator. The separator pulls out reinforcing steel and other ferrous metals. This step raises the quality of the recycled aggregate. At the same time, it recovers scrap metal that you can sell as an extra source of income.

Next, the screening stage sorts the crushed material into size ranges such as 0–5 mm, 5–20 mm, and 20–40 mm. Any particles larger than the target size return to the crusher. The system keeps running this loop in the construction waste crushing process until all material reaches the required size.

Stage 5: Secondary and tertiary crushing

If the market needs finer recycled aggregates or tight size control, you add a secondary or tertiary stage. In this phase, you run the material through impact or cone crushers. These machines refine the product and shape it. They help you make high‑quality sands and gravels for demanding uses.

- Secondary crushing receives the product from primary crushing and reduces it to sizes suitable for use in subbases or stabilized bases.

- Tertiary crushing produces recycled sands and fines suitable for non-structural concrete and specific surface courses, provided regulations permit.

Stage 6: Collection, quality control and dispatch

The process of crushing construction waste ends with the stockpiling of the various recycled aggregates. It is crucial to keep the piles separate by size and quality, avoiding mixtures that could complicate the material certification process for clients.

Good practices:

- Periodic monitoring of particle size distribution, density, and contaminant content.

- Clear labeling of each stockpile: type of waste from origin, nominal size, and potential use (road base, fill, recycled concrete, etc.).

Economic benefits of recycling and shredding construction waste

Implementing a construction waste crushing process generates several direct benefits in construction costs. Transportation expenses to landfills, final disposal fees, and the purchase of natural aggregates, which are already expensive in many countries, are reduced.

Furthermore:

- Mobile construction waste crushing plants allow for on-site processing of the material, shortening construction times and decreasing dependence on external quarries.

- The recycled aggregate can be sold to third parties, opening a new revenue stream for construction companies and demolition contractors.

Frequently Ask & Questions

The construction waste crushing process consists of several clear steps. First, you receive construction and demolition debris such as concrete, brick, and asphalt. Then you pre‑sort the material to remove items that do not fit the process. Next, you crush and screen the debris to reach the target sizes. In the end, you obtain recycled aggregates ready for use in new construction projects. This reduces landfill waste, saves on the purchase of natural aggregates, and promotes more sustainable waste management.

A typical line uses vibrating feeders and jaw or impact crushers. These units can be stationary or mobile on tracks or wheels. Magnets remove steel from the crushed material stream. Vibrating screens then sort the recycled aggregate by size. For high-volume or spread-out projects, mobile plants are widely used. They combine several key functions on a single frame.

The main benefits are lower transport and landfill costs. Companies also buy less new aggregate for their projects. In many cases, they earn extra money by selling recycled aggregate. Crushing construction waste also cuts the project’s environmental impact. It reduces pressure on quarries and landfill sites. At the same time, it supports rules that promote a circular economy.

Construction waste should arrive as clean as possible. Impurities like wood, plastics, plaster, and hazardous waste must be low. These contaminants reduce the quality of the recycled aggregate. Steel and other metals also need strict control. They should be removed with magnetic separation systems. After that, the material must be well screened. This gives a stable particle size that fits its final use.