Email: [email protected]

Crush Building Material: Types, Crushing Technology & the Right Crushers

Hey there! If you’ve ever admired a sturdy skyscraper or driven on a smooth highway, you’ve seen the magic of crush building material in action. Obviously, it’s not glamorous, but trust me – it’s the basis of almost everything we build. First, let’s analyze why this gritty hero deserves your attention.

What Exactly is Crushed Building Material?

Simply put, it’s rock, concrete, or masonry broken down into smaller fragments. Think of gravel, sand or recycled concrete, for example. These materials are undoubtedly the “skeleton” of a building, providing stability, drainage and volume. Before, I had walked through quarries where large crushers broke huge boulders into perfectly uniform stones. Clearly, this is raw power being harnessed to create!

Top Types of Construction Crushed Materials

- Granite & Basalt Aggregates: Super dense and ideal for high-strength concrete.

- Recycled Concrete Crush: Eco-friendly and cost-effective—diverting waste from landfills.

- Limestone Gravel: Perfect for drainage layers under roads (I’ve seen it prevent countless potholes!).

- Sand & Fine Aggregates: The unsung hero in your mortar and asphalt mixes.

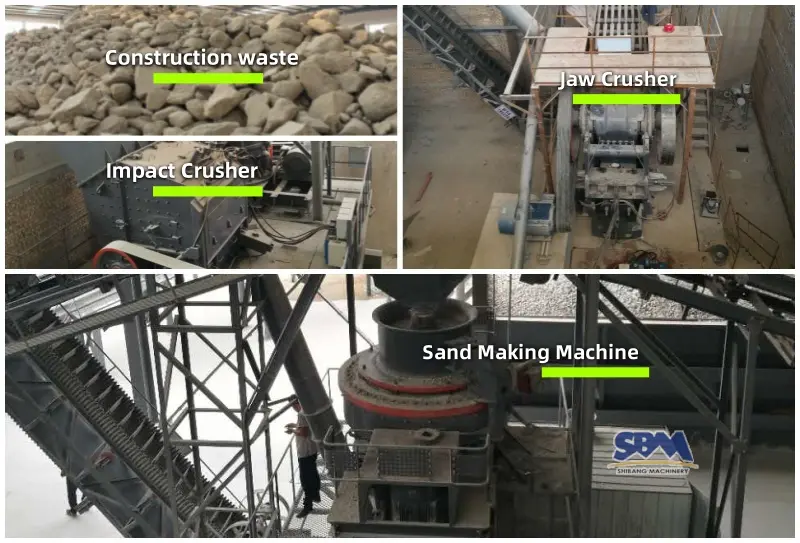

How Crushing Technology Transforms Raw Rock?

Modern crushers (like those from SBM China) are engineering marvels. Generally, jaw crushers do the heavy crushing first, while cone crushers refine the crushed material. But mobile crushers? They are game-changers – processing crushed rock on-site at rates of 100-500 tons per hour! As an example, I remember one demonstration where a mobile plant turned demolition waste into roadbed right on the spot. The efficiency goal? Crushing.

Where You’ll Find Crush Building Material in Action?

- Road Sub-Bases: 70% of road layers are crushed stone—providing stability.

- Concrete Production: Up to 80% of concrete volume is aggregates.

- Landscaping: That lovely garden path? Likely 10–20mm gravel.

- Railway Ballast: Angular crushed stone keeps tracks aligned.

3 Reasons Smart Builders Prioritize Quality Crush

- Cost Efficiency: Recycled crush cuts material costs by 30–50%.

- Sustainability: Using recycled aggregates reduces mining demand. (Our planet says thanks!)

- Durability: Well-graded crushed stone prevents structural settling.

Choosing the Right Crusher for Your Project

Not all crushing is created equal! Obviously, the particle size (0-5mm sand vs 40mm gravel) depends on your crusher configuration. For example, SBM’s multi-stage crushing plant allows you to adjust the output, thus achieving more precise crushing. First, a pro tip: if your site is frequently relocated, choose a mobile crushing plant. Because less transportation = more economical budget.

| Type | Capacity | Primary Uses | Pros | Cons |

|---|---|---|---|---|

| Jaw Crusher | 50-1,500 tph | – Primary crushing – Processing of hard rock (granite, basalt) – Mining | ◾ Strong structure, simple maintenance ◾ Strong ability to handle large bulk materials ◾ Suitable for high hardness materials | ◾ Uneven particle size of the discharge material ◾ High energy consumption ◾ Loud noise (measured >85dB) |

| Cone Crusher | 100-800 tph | – Secondary/tertiary crushing – Production of fine aggregate (<30mm) – Concrete/Asphalt Mixture | ◾ Excellent particle shape of the output material (high proportion of cubes) ◾ Low wear parts costs ◾ High degree of automation (such as SBM hydraulic system) | ◾ High initial investment ◾ Sensitive to sticky materials ◾ Complex structure, maintenance requires professional skills |

| Impact Crusher | 80-500 tph | – Medium soft rock crushing (limestone) – Recycling of construction waste – Production of machine-made sand | ◾ Flexible particle shape adjustment ◾ Energy saving (30% lower energy consumption than jaw crusher) ◾ Powder content is controllable (5-20%) | ◾ Rapid wear of blow bars (hard rock conditions) ◾ Loud noise and dust ◾ Not suitable for materials with high silicon content |

| Mobile Crusher | 100-400 tph | – On-site construction waste recycling – Temporary quarry operations – Remote Area Projects | ◾ 24-hour rapid deployment ◾ Save transportation costs (on-site conversion rate 85%+) ◾ Intelligent control (such as SBM EPC system) | ◾ Single machine capacity is limited ◾ High equipment price ◾ Requires supporting power supply/fuel support |

Related Contents: How to Choose The Right Crusher for Hard Rock?

Crusher Selection Tips (From My Site Visits!)

- Hard rock mining → Jaw crusher + cone crusher combination (such as SBM’s HPT series, which has been measured to increase granite crushing efficiency by 40%)

- Recycling of demolition waste → Mobile impact crusher (directly produce 0-32mm recycled aggregate on site, and equally important, saving freight is the key!)

- Machine-made sand production → Vertical shaft impact crusher (VSI) + cone crusher (the best control of powder content is 12-15%)

Need detailed parameters for a specific model? Please be sure to tell me your material hardness (Mohs hardness) and target output power. I will recommend a suitable solution for you as soon as possible! 💡

Mohs hardness of some stones: How To Crush Rocks? Simple Information Sharing

The Future: Smarter, Greener Crushing

The industry is racing to develop electric crushers and AI-powered sorting. In short, imagine zero-emission plants producing carbon-neutral aggregates! Finally, I’m excited about innovations like the SBM crusher – drastically reducing energy consumption while maintaining power.

Wrapping It Up

Next time you see a pile of crushed stone, remember: it’s not debris. In fact, it’s the engineered material that keeps our world going. Whether it’s rock or recycled concrete, quality crushed stone building materials mean tough, resilient things beneath our feet.