Email: [email protected]

Limestone crushing vs. grinding: how to choose the ideal process

When working with limestone, the big question isn’t just what equipment to buy, but how far to go: do I stick with limestone crushing or do I also invest in fine or ultrafine limestone grinding? This decision defines your investment, your energy consumption, the quality of the final product, and ultimately, your profit margin.

In Latin America, many clients start with a simple limestone crushing line to produce aggregates or kiln feedstock, only to discover later that the market pays more for finer ground limestone. This article clarifies the differences between crushing and grinding limestone, providing examples, tables, and practical advice to help you make informed decisions.

Crushing vs. grinding

In comminution, “to crush” and “to grind” are not the same, although in colloquial language they are sometimes mixed up.

- Limestone crushing involves reducing large rocks (30–1000 mm) to coarse or medium sizes, typically between 5 and 50 mm, mainly using compression or impact forces.

- Limestone grinding takes that crushed material and reduces it to fine powders, from about 2 mm down to very fine sizes such as 200–325 mesh (≈75–44 μm) or even less than 10 μm in ultrafine mills.

In summary: limestone crushing = coarse product for aggregates and kiln feed; limestone grinding = fine powder for cement, fillers, agricultural lime and industrial additives.

Properties of limestone that affect the process

Before comparing crushing vs. grinding limestone, it’s important to understand the material. Limestone is a sedimentary rock of moderate hardness (≈3–4 on the Mohs scale), composed mainly of calcium carbonate.

These characteristics directly influence your limestone processing plant:

- Relatively low hardness: allows the use of compression equipment (jaw crusher, cone crusher) and impact crushers without extreme levels of wear.

- Tendency to generate fines and dust: both in limestone crushing and limestone grinding, you need good dust collection or to work in wet conditions to improve the environment and recover product.

Depending on the purity, moisture, and presence of clays or abrasive silica, the crushing vs. grinding scheme for limestone may require adjustments to liners, crushing chambers, and mill type.

What is limestone crushing?

Limestone crushing is the first reduction stage, where the size of quarry blocks is reduced to sizes suitable for transport, stockpiling, or feeding mills. A typical limestone processing line includes:

- Primary crushing: normally with a jaw crusher or heavy impact crusher, receiving rocks of 300–800 mm.

- Secondary (and sometimes tertiary) crushing: with a cone or impact crusher to reduce the material to 5–40 mm, depending on the final use.

Limestone crushing is usually done in dry conditions, using conveyor belts, vibrating screens, and dust collection systems.

Typical equipment for limestone crushing

In limestone processing plant projects, three main types of crushers are used: jaw, impact, and cone.

- Jaw crusher for limestone:

Ideal as a primary crusher; it accepts large feed sizes and has a simple structure and moderate initial cost. - Impact crusher for limestone:

Very popular when good cubicity is required in aggregates and high reduction in secondary/tertiary stages. - Cone crusher for limestone:

Recommended when a more uniform product with high capacity and good quality is required for asphalt or concrete mixes.

In mobile applications for infrastructure projects in Latin America, mobile limestone crushing plants combine jaw + impact or cone on tracked or wheeled chassis, facilitating quick assembly in small quarries.

What is limestone grinding?

Limestone grinding begins where limestone crushing ends. Its objective is to produce fine or ultrafine powder with controlled size distribution for applications such as cement, flue gas desulfurization, glass, steel, agriculture, and mineral fills.

The typical flow in limestone grinding is:

- Storage of crushed limestone (5–30 mm).

- Feed to the limestone mill (vertical, Raymond, ball mill, ultrafine mill, etc.).

- Classification by separator or cyclone; the coarse material is returned to the mill, the fine product is sent to silos or packaged.

In some cases, wet milling is used, especially for very fine powders with high size control requirements and low dust generation.

Typical equipment for limestone grinding

In a modern limestone processing plant, the selection of the limestone mill is key to energy consumption and powder quality.

In the industrial sector, the following are mainly used:

- Ball mill for limestone: versatile, suitable for dry or wet grinding, widely used in cement.

- Raymond mill for limestone: a good option for medium fineness (e.g., 80–325 mesh) with reasonable energy consumption.

- Vertical limestone mill (type LM): integrates crushing, drying, grinding and classification into a single unit, with capacities of 3–340 t/h and input sizes up to 70 mm, thus reducing previous crushing stages.

- Ultrafine mills (SCM type): designed for very fine powders (down to a few micrometers) with capacities of 0.5–25 t/h for materials such as high-purity limestone.

The choice between these equipment depends on the target fineness, the required capacity, and the investment and operating budget.

Key differences between crushing and grinding

Although limestone crushing and limestone grinding are part of the same comminution chain, their objectives and results are very different.

Product size

- Limestone crushing: produces aggregates of 5–50 mm; in tertiary crushing, it can be reduced to 0–5 mm (limestone sand).

- Limestone grinding: generates powders from 2 mm down, reaching 75 μm (200 mesh) in classic mills or less than 10 μm in ultrafine equipment.

Simply put: if you can see the grains and handle them like gravel or sand, you’re coming from crushing; if the material resembles flour or talc, you’re in milling.

Energy and investment

Limestone grinding always consumes more energy per ton than limestone crushing because the size reduction is much greater and falls within the range of individual particle behavior. This translates to:

- Increased installed capacity in mills and classifiers.

- Greater sensitivity to ventilation capacity, humidity, and material characteristics.

That’s why many projects in Latin America start with a simple crushing line versus a complete limestone grinding line, and expand to grinding only when the market justifies it.

Quick summary of limestone crushing vs. grinding

| Aspect | Limestone crushing | Limestone grinding |

|---|---|---|

| Typical output size range | 5–50 mm (sometimes 0–5 mm in tertiary) | 2 mm to 75–10 μm depending on the mill |

| Stage at the plant | Primary / Secondary / Tertiary | Final stage of comminution |

| Main Equipments | Jaw crusher, impact crusher, cone crusher, mobile plant | Ball mill, Raymond mill, vertical LM mill, ultrafine SCM mill |

| Specific energy consumption | Low-medium | Medium-high |

| Initial investment | Lower per t/h installed | Higher per t/h fine |

| Typical applications | Aggregates, road base, kiln feed | Cement, desulfurization, fillers, agricultural lime |

Particle size difference

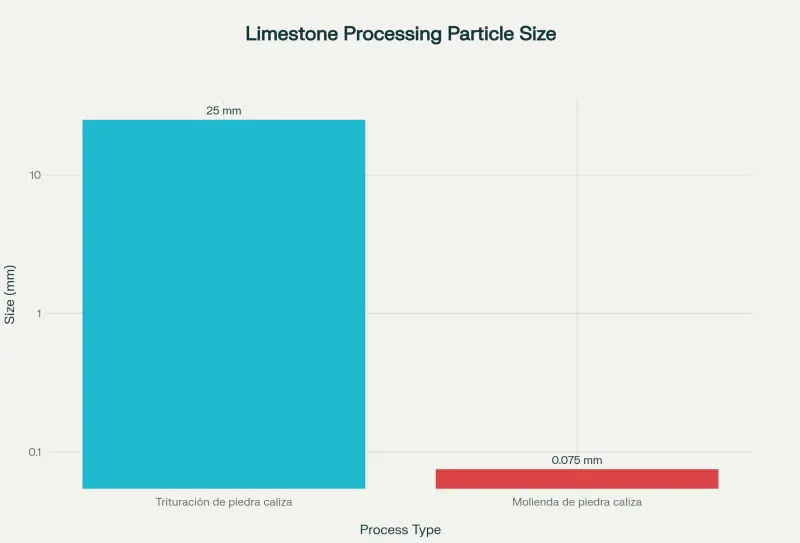

The following visual comparison helps to illustrate the gap between crushing vs. grinding limestone:

- Crushing limestone yields, on average, a particle size of around 25 mm when working within the 5–50 mm range.

- Limestone grinding can deliver average sizes on the order of 0.075 mm (75 μm), typical of 200 mesh powders.

This huge difference in size explains why limestone grinding requires much more care in mill selection, classification, and fineness control.

When is limestone crushing alone sufficient?

In many Latin American operations, a well-designed limestone crushing line already covers a significant portion of the business. Limestone crushing alone is usually sufficient if:

- Produces aggregates for concrete and asphalt, such as 0–5, 5–10, 10–20 or 20–40 mm.

- You sell crushed limestone for road bases, fill, or ballast.

- You supply lime or cement kilns that accept limestone in 20–80 mm pieces for their own internal grinding system.

In these cases, the discussion is not about crushing vs. grinding limestone, but about which configuration of crushers and screens gives you the best particle size distribution and cost per ton.

When do you also need limestone grinding?

Limestone grinding comes into play when your market demands added value:

- Production of cement or premixes where limestone must enter the process in the form of fine powder.

- Flue gas desulfurization (FGD) systems in thermoelectric power plants, which require aqueous suspensions of finely ground limestone.

- Mineral fillers for paints, plastics, paper or glues, where surface quality and fineness are critical.

- Agricultural lime and soil conditioners, where a finer powder improves reaction speed and distribution.

In these scenarios, the decision is not crushing vs. grinding limestone, but which combination of both gives you the most competitive total cost per ton.

Typical flow: from quarry to fine powder

A standard limestone processing plant layout that combines limestone crushing and limestone grinding looks like this:

- Quarrying and blasting: obtaining limestone blocks.

- Primary crushing: jaw crusher for limestone or heavy impact.

- Secondary/tertiary crushing: impact or cone crushing to achieve 5–30 mm.

- Storage and dosing: silos or hoppers for crushed limestone.

- Limestone grinding: LM vertical mill, Raymond mill, ball mill or ultrafine mill depending on the desired fineness.

- Classification and pneumatic transport: separator or cyclone, then silos and bulk or bagged packaging.

Each stage must be sized consistently to avoid bottlenecks and excessive recirculation.

Select crushers for limestone

When considering limestone crushing for Latin American clients, the crusher selection depends on:

- Hardness and abrasiveness of limestone.

- Maximum feed size.

- Capacity in t/h.

- Grain shape requirements (cubic vs elongated).

Practical guidelines:

- Robust jaw crusher as a first stage for large blocks, with low initial cost and simple maintenance.

- Impact crusher for limestone when the priority is good cubic shape for concrete and asphalt mixtures, and abrasiveness is not extreme.

- Cone crushers are used when the limestone processing plant demands high capacity and a finer product with a lower fines content.

For projects with multiple quarry faces or construction contracts, mobile limestone crushing plants offer flexibility and reduce raw rock transportation costs.

Select limestone mills

In limestone grinding, the choice of mill is as important as the choice of quarry. Some guidelines:

- Medium-speed Raymond/MTM mill:

Ideal when you need medium fineness (e.g., 80–325 mesh) with typical capacities of 3–22 t/h for limestone, with low energy consumption. - LM vertical mill for limestone:

Highly suitable if you are looking to integrate crushing, drying, and grinding in a single unit, accepting feed down to 70 mm, with capacities of 3–340 t/h, which can reduce the number of crushers required. - SCM ultrafine mill:

When your customers require ultrafine powders with high whiteness for special applications, with capacities of 0.5–25 t/h for high-purity limestone.

The best strategy is to align the required fineness (e.g., 200, 325, or 1250 mesh) with the type of limestone mill that offers the lowest energy cost per ton within the desired production range.

Operating costs: energy, spare parts and maintenance

The economic comparison between crushing and grinding limestone doesn’t end with the equipment bill; you have to look at the daily operation.

In general:

- Limestone crushing exhibits lower specific energy consumption and moderate wear, especially with jaw crushers and cone crushers in medium-hardness limestones.

- Limestone grinding accounts for the majority of electrical consumption, as well as wear on grinding media and internal linings.

Therefore, when sizing your limestone processing plant, it is advisable to:

- Optimize the particle size distribution curve in limestone crushing to ensure the mill processes a homogeneous feedstock and avoids wasting energy breaking unnecessarily large blocks.

- Adjust the classification circuit to prevent over-grinding of already fine particles, which only increases electricity consumption without adding value.

Product quality: shape, fineness, and distribution

The quality of the material produced in the crushing and grinding of limestone is evaluated differently.

In limestone crushing, customers typically look at:

- Cubic aggregate form (minimal needle and flake size).

- Continuous gradation that meets standards for concrete or asphalt.

In limestone grinding, however, the following rule:

- Fineness, measured in mesh (e.g., 200, 325) or in microns.

- Narrow size distribution, depending on the end use (cement, FGD, fillers).

If your end customer is a cement plant, for example, the limestone grinding must be integrated with the rest of the raw materials to ensure a homogeneous and stable mixture.

Typical use cases in Latin America

In practice, the most frequent combinations of limestone crushing and grinding in the region are:

- Aggregate Quarry + Crushed Stone Sales:

Crushing of limestone only, multiple fractions for construction. - Small-Scale Lime and Cement Producer:

Crushing and grinding of limestone using a ball mill or Raymond mill to supply kilns and for local sales. - Integrated Industrial Cement or Lime Plant:

Complete limestone processing plant layout with primary/secondary crushing, pre-homogenization, and specific grinding according to your process. - Filler and Agricultural Lime Producers:

Focus primarily on limestone grinding, purchasing crushed limestone from third parties or a partner quarry.

How to decide: practical questions

To determine if your project requires only limestone crushing or also limestone grinding, answer these key questions:

If your market buys 0–5, 5–20, or 20–40 mm, a good limestone crushing line is sufficient.

If they require 200–325 mesh powder, you absolutely need limestone grinding.

A common strategy in Latin America is to start with limestone crushing and reserve physical and electrical space for future mills.

Limestone grinding has high fixed costs; it’s advisable to have stable contracts or clients before oversizing the system.

Configuration Recommendations by Project Type

As a quick guide for you:

- Small quarry for local construction (50–150 t/h):

Limestone crushing line with primary jaw crusher + secondary impact or cone crusher, one or two screens, and product silos. - Agricultural lime and basic filler plant (30–100 t/h of powder):

Crushing to 0–30 mm + medium-speed Raymond or MTM mill for 80–325 mesh, with separator and bagging. - Integrated vertical cement or lime plant (100–500 t/h):

Limestone crushing + LM vertical mill for raw grinding or specific limestone grinding, taking advantage of its capacity to integrate drying and classification. - Specialized producer of ultrafine limestone:

Pre-crushing to 0–10 mm + SCM ultrafine mill, prioritizing high whiteness and narrow size distribution.