Email: [email protected]

Efficient concrete crusher for construction and mining

The choice of aconcrete crusher Appropriate makes the difference in any industrial project, whether construction, demolition or mining. If you have ever felt the hassle of searching for accurate information among so many options, Don't worry! Here I explain easily and directly how to make the best decision for your company.

What is a concrete crusher?

Aconcrete crusher It is a machine designed to crush concrete waste, blocks and other building materials, allowing its recycling or efficient reuse in new works.

- It uses hydraulic or mechanical systems to break concrete into small sizes.

- Helps reduce costs in works and projects by taking advantage of recycled material.

- Facilitates the handling and transportation of debris.

Advantages of using SBM concrete crusher

choose onesbm crusher has several key benefits:

- High energy efficiency and low consumption.

- Reduced maintenance cycles and simple operation.

- Adaptability for different types of materials and production scales.

- Multiple models: stationary or mobile, depending on the workplace.

Main types of concrete crusher

Concrete crushers are divided into several types according to their functions and environment.:

| Crusher type | Main application | Ability (TPH) | Motion | Main advantages |

|---|---|---|---|---|

| Trituradora de mandíbula | Break big blocks | 50–1000 | Stationary/Mobile | Easy maintenance, robustness |

| Trituradora de impacto | Recycling, demolition | 100–850 | Stationary/Mobile | Energy savings, versatility |

| Trituradora móvil hidráulica | Remote projects, flexibility | 0–650 | Mobile | Mobility, quick setup |

Technical parameters: CI5X SBM crusher example

If you are looking for technical specifications of SBM products, Here is an example referenced to the CI5X Impact Crusher range:

| Model | Feeding size | Production capacity | Engine power | Total weight |

|---|---|---|---|---|

| CI5X1315 | Until 1000 mm | Until 850 t/h | 200–250 kW | 25,5 t |

How to select the right crusher?

To choose yourconcrete crusher, consider these key points:

- Volume and type of material to be processed.

- Power format and desired output.

- Energy requirements and available space.

- Total operation and maintenance cost.

- Level of automation and ease of use.

It's not easy to get the perfect idea the first time., But with these criteria, the project is sure to go from strength to strength.. Always ask about after-sales service and availability of spare parts.

Key technical advantages of SBM over the competition

A differential of SBM is its focus on modularity and efficiency:

- Modular design easy to upgrade and scale.

- Optimized engines and hydraulic systems.

- Reduction of investment and maintenance costs.

- High degree of automation and operational security.

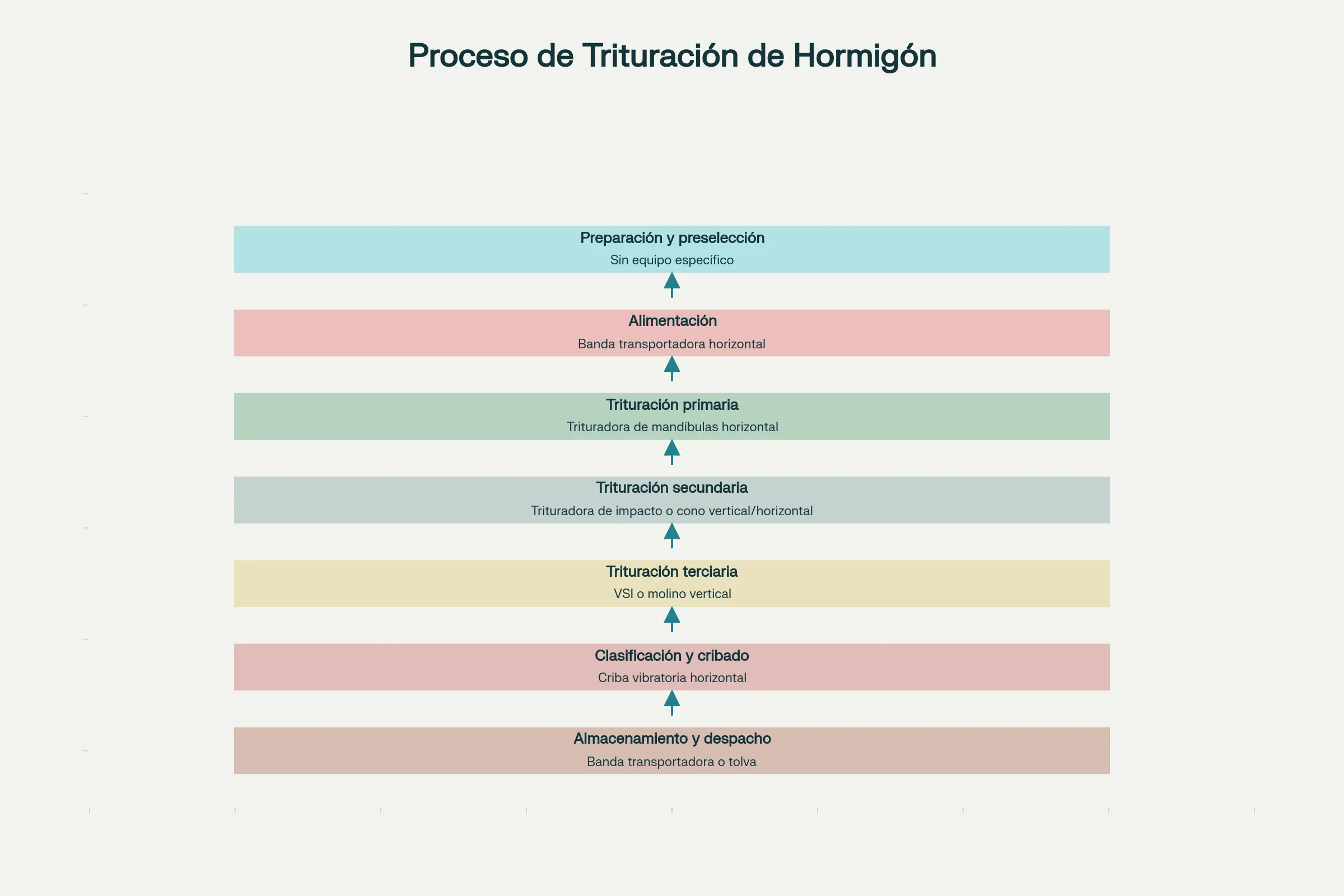

Graphics: Concrete crushing process

Recommendations for use and maintenance

It's not just about buying a machine!! Here are some tips to squeeze every euro out of your investment.:

- Maintain centralized cleaning and lubrication routines.

- Perform periodic checks of the hydraulic and electrical system.

- Train your operators in safety and fast operation.

This prevents downtime and improves long-term durability.. SBM offers technical support and original spare parts: ask without fear!

FAQs: Frequently asked questions about concrete crushers

It is recommended between 100–400 t/h depending on the amount of concrete processed.

Depends on the model, but SBM stands out for low costs and affordable spare parts.

Yeah, SBM models support materials such as granite, limestone or mixed rubble.