Email: [email protected]

Crushed Stone and Gravel Crusher: Practical Guide to Decide

What is crushed gravel? Uses and advantages

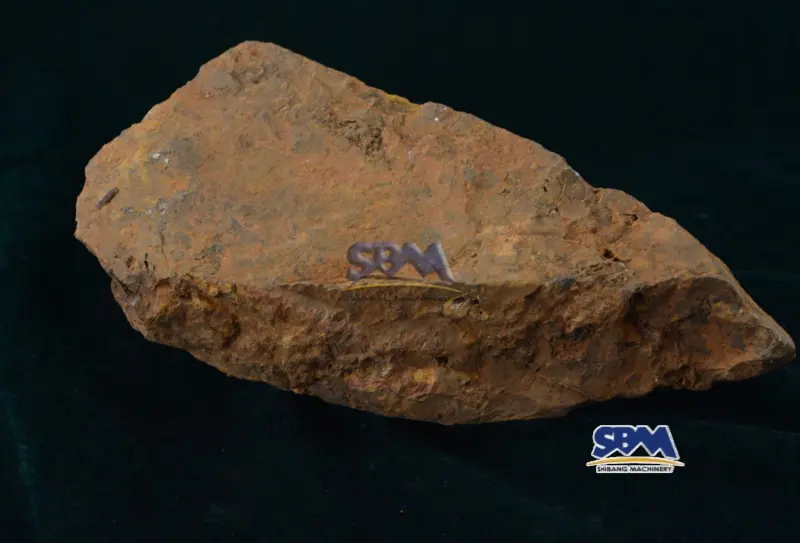

Crushed gravel is one of the most common and valued materials in construction and mining.. Basically, obtained by breaking large rocks with specialized machinery, forming angular fragments of different sizes that are used for concrete, roads, bases and fillers.

What makes crushed gravel special is its strength and compaction capacity.. Thanks to its shape and cleanliness, helps achieve more uniform mixes and more durable concrete than using only river gravel or sand.

Among its advantages are:

- High resistance and durability in all types of structures.

- Better drainage in soils and road bases.

- Competitive prices, ideal for works and quarries in Latin America.

- Versatility for concrete, drainage, fill and roads.

That's why, Crushed gravel is an ally both in road projects and in industrial foundations and mineral plants.

Crushed gravel manufacturing process

I tell you, The process usually begins in the quarry with the extraction of rock, which is then taken to a crushing plant. Using jaw crushers, impact or cone, The stones are broken until the desired size is obtained.. Finally, Industrial screens separate the fragments according to their measurements.

The stages of the process are:

- Extraction: use of explosives or heavy machinery.

- Primary crushing: with jaw crushers.

- Secondary crushing: with impact or cone equipment.

- Classification: sieves to separate the different sizes.

- Washing: to remove dust and clay, according to the requirements of the project.

This chain ensures uniformity and quality, essential requirements in professional projects.

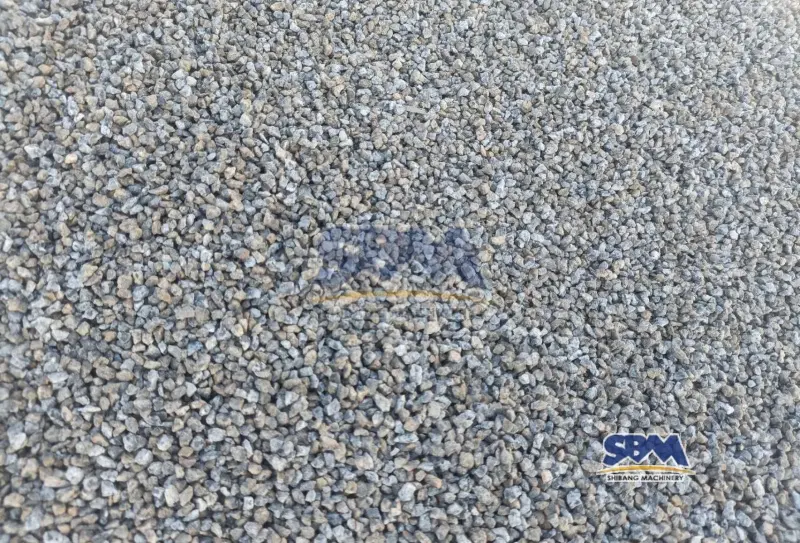

Types and Applications of Crushed Gravel

Crushed gravel is not all the same. Its size and quality depends on the machinery used and the mineral of origin.. Some examples that clients in Latin America usually request:

| Gravel Type | Size (mm) | Typical use |

|---|---|---|

| An important final | 2–8 | Finishes, decorative concrete |

| Grave median | 8–16 | Structural concrete, stuffed |

| coarse gravel | 16–32 | road bases, drainage |

| crushed stone base | 38–65 | Foundation, soil protection |

| Washed engrave | Variable | High quality concrete |

If you have doubts between fine and coarse gravel, It is best to speak with a local provider who will advise you., because the demands change depending on the soil and the work.

What is a stone crusher? Types and options for mineral processing

A stone crusher is the heart of any processing plant: Transform huge blocks into useful aggregates quickly, efficient and economical. In Latin America, These teams have various names.: crushers, breakers, impact crushers, Pussy, jaw or rollers.

General operation of a crusher

These teams take advantage of the mechanical advantage: apply pressure, impact or cut to break the large rock into increasingly smaller pieces. The material that comes out may be coarse crushed stone, important final, or even industrial sand depending on the equipment configuration.

Main types of stone crushers

| Crusher type | Ideal for | Capacity approx.. | Key feature |

|---|---|---|---|

| Mandíbula | hard rocks, mining | 105–1590 t/h | High robustness and reliability |

| Impacto | Limestone, soft materials | 60–2000 t/h | Cubic shape, it was easy. |

| Cono | Secondary and tertiary | 85–2181 t/h | Uniform granularity |

| Hammer | Brittle materials | 3–95 t/h | High reduction, economic |

| Roller | Fines and sands, clays | 3–110 t/h | Great uniformity |

| Giratoria | Large volume, abrasive rocks | 2354–14082 t/h | Industrial plants |

How to choose the right stone crusher?

Not all crushers work the same for all types of rock or applications. When choosing, the key factors are:

- Material type: granite, limestone, iron ore, etc.

- Required capacity: depends on the daily volume and the size of rock to be processed.

- Quality of the final product: if you are looking for cubic stone, little generation of fines, etc.

- Space and ease of operation: mobile plants vs. fixed, maintenance, energy consumption.

Practical example: for arena silica or caliza industrial, an impact crusher or VSI may be more efficient. But, if you are looking for resistant concrete bases, nothing like one with a robust jaw.

Advantages of using crushers and their contributions to your project

It's not just because of tradition: Having a good crusher makes a difference in savings, quality and flexibility in work.

- Cost savings: reduces spending on transportation and purchase of materials, processing local stone in situ.

- Material customization: You can adjust the size and shape according to the requirement of your work.

- Environmental improvement: you will bring back the leftovers, You reduce the impact of transportation and take advantage of demolition or recycling materials.

- Professional performance: Modern equipment is energy efficient and easy to operate.

Trends and advantages of mobile crushing machinery in Latin America

in the region, Modernization of mines and urban construction has boosted demand for mobile crushers, that provide installation speed, less need for infrastructure and better adaptability to remote or difficult-to-access projects.

- Integration and automation: modern plants include smart systems, suitable to operate even where specialized technicians are lacking.

- Greater flexibility: changing locations is easy, Just move the plant without disassembling it.

- Quick turnaround: Greater speed of execution means faster deliveries and satisfied customers.

Final considerations, maintenance and after-sales service

Investing in a modern stone crusher or crushed gravel plant requires reviewing local technical support, the availability of spare parts and that the equipment meets international standards. Always consult the technical sheet and be sure to compare recognized suppliers in the industry, such as SBM or verified international brands (“mobile crushers”, “industrial crushers”, etc.).

Finally, don't underestimate routine maintenance: A plant stopped due to poor service or lack of spare parts can cost much more than the initial investment.

Comparative table: Applications and benefits

| Application | Crushed Grava | Stone Crusher |

|---|---|---|

| Roads and highways | High compaction and durability | Production of bases according to standard |

| Concrete and concrete | Better adhesion and resistance | Control over aggregate size |

| Mining and filling | Good stability and waterproofing | Cost savings, local processing |

| Urban planning/quarries | Versatility in finishes and compaction | Demolition material reduction |

Tips for your entrepreneurship

If you have a quarry, or do you plan to open a plant, research the local market well and offer quality, immediate service and stock. Customers value constant availability and personalized advice to choose the correct equipment and material.

I have had to see how good shredding can make the difference between a job that completes and another that is delayed or fails.. So, Invest in training and trust in your teams—and your wallet will notice it.

FAQs about stone crushers and crushed stone.

It is ideal for road bases, concrete structures, fillings, foundations and drainage, due to its great compaction capacity and stability.

There is fine gravel, medium and thick, oscillating normally between 2 mm up to 38 mm. The choice depends on the use: Structural bases require 3/4 gravel″, while for roads you can choose thicker.

Mobile crushers are ideal for temporary projects or small quarries; fixed ones offer greater capacity and efficiency in large industrial applications.

mineral type, production capacity, desired final size, operating costs and ease of maintenance.

Periodic inspection, component lubrication, replacement of worn parts and thorough cleaning to avoid blockages and prolong service life.

Using the wrong type of gravel for structural foundations, or buy equipment without after-sales support or professional advice, These are common mistakes that can be expensive..