Email: [email protected]

A Good Guide to Choosing a Vertical Shaft Impact Crusher

Choosing the right vertical shaft impact crusher (VSI) for a business that processes stone or makes aggregates can be tough. With so many choices and details to compare, it’s easy to get confused. This article will explain all the important points, making it simpler for buyers to pick the right crusher and save money.

What is a Vertical Shaft Impact Crusher?

A vertical shaft impact crusher, also known as a VSI crusher, is a type of machine that turns raw materials into fine, evenly shaped products, such as sand or special gravel. Instead of squeezing the stone, this crusher throws the material at high speed inside the machine. The stones hit either metal plates or other rocks, which breaks them apart. Because of this, VSI crushers are great for making high-quality sand and for improving the shape of materials used in concrete.

How VSI Crushers Work?

VSI crushers move stones quickly through a spinning rotor. After being spun around, the material hits the inside wall of the crusher—either a metal plate or a layer of rock—which causes it to break naturally.

- Rock-on-rock and rock-on-iron options: This means the stones can hit either other stones or a metal surface inside the machine, giving different product shapes and performance.

- Centrifugal impact: This special way of moving and breaking the rock helps create even, cube-like pieces with fewer oversized chunks.

Typical Applications

VSI crushers deliver outstanding results in applications such as:

Key Product Parameters

Knowing the basics of VSI crusher specs helps make sure the chosen machine fits what the plant needs. The table below shows the main VSI crusher features from top brands like SBM, M*KA, and others:

| Model | Max Feed Size (mm) | Capacity (t/h) | Motor Power (kW) | Rotor Speed (rpm/m/s) | Weight (kg) |

|---|---|---|---|---|---|

| SBM VSI6X | 45 | 110–583 | 220–400 | 1100–1500 | ~19,000 |

| M*KA M*I 90L | 50 | 200–400 | 200–400 | 800–1700 | 9,210–12,450 |

| Con*tmach VSI | 35–90 | 60–300 | 110–400 | 45–70 m/s | 6,500–15,000 |

| AM*CO V70 | 40 | 100–200 | 160–320 | 1500–1800 | 11,000 |

Note: Product specifications vary; always match with site-specific requirements.

Types of VSI Crushers and Their Features

1. Rock-on-Rock vs. Rock-on-Iron

What to Consider When Choosing a VSI Crusher?

Performance and Output

Energy Efficiency

VSI Crusher Advantages and Disadvantages

| Advantage | Disadvantage |

|---|---|

| Excellent cubical end product | Higher initial cost |

| High reduction ratio, great for sand/aggs | Sensitive to oversize feed |

| Energy-efficient with lower wear (rock-on-rock) | Requires regular rotor and anvil check |

| Versatile: sand production, aggregate shaping | More complex settings than jaw/crushers |

VSI Crusher Market Trends and Applications

Increasing Demand for High-Quality Sand

With concrete and asphalt standards evolving, it’s more important than ever to deliver aggregate with tight tolerances and optimal particle shape. VSI sands usually meet strict standards for gradation and structure.

Multiple Industries Using VSI Technology

- Construction (highways, bridges, ready-mix concrete)

- Mining and mineral beneficiation

- Glass, ceramics, and waste recycling

VSI Crusher Maintenance Tips

- Regularly inspect rotor and anvil conditions for wear

- Maintain lubrication systems—lack of oil is a leading cause of breakdowns

- Monitor vibration and operating sound for early warnings of trouble

Choosing an SBM VSI Crusher: Advantages

SBM is the biggest maker of crushing machines in Asia, so their vertical shaft impact crusher offer:

VSI Crusher Selection Chart

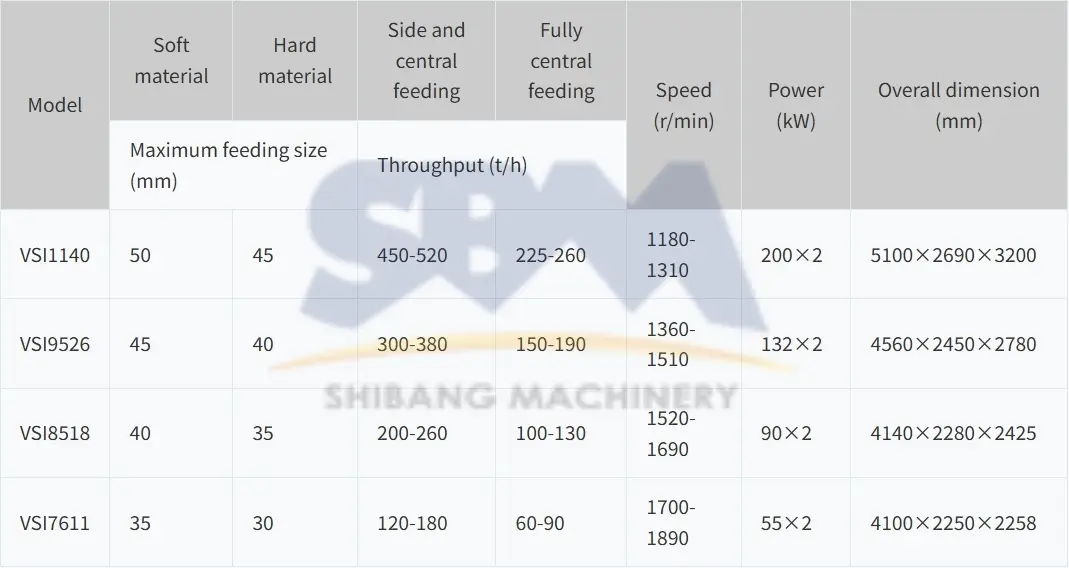

VSI Sand Maker Parameters:

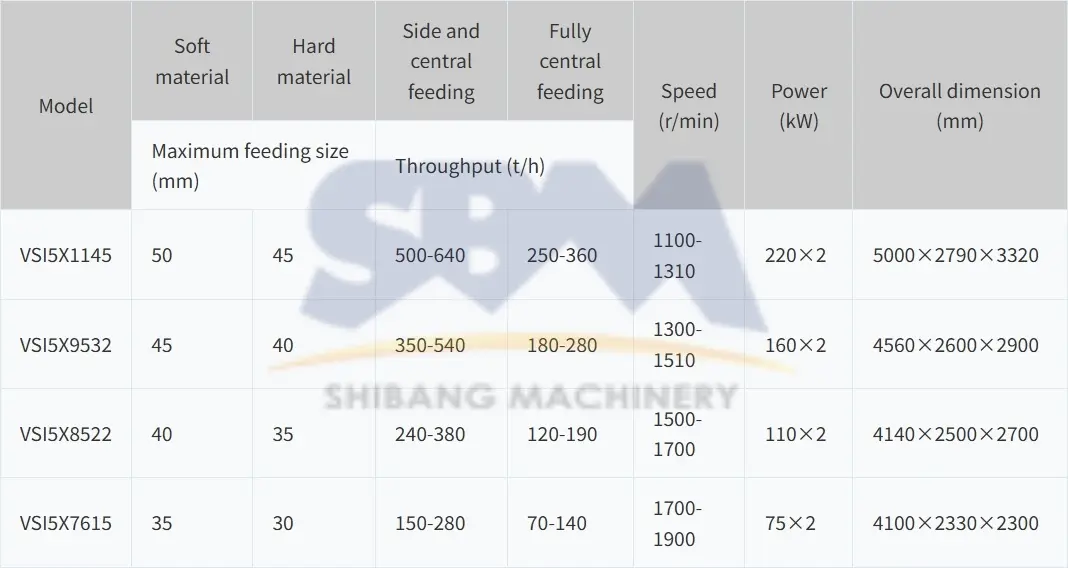

VSI5X Sand Making Machine Parameters:

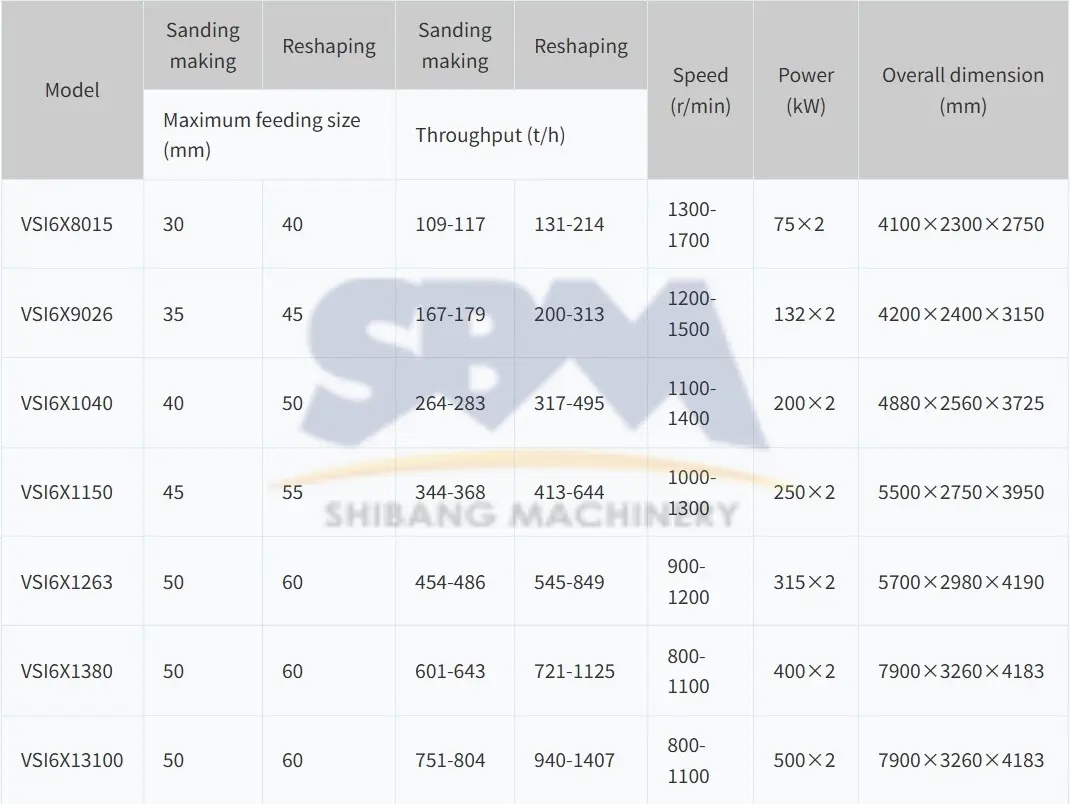

VSI6X Crusher Parameters:

VSI Practical Selection Guide

- Define Application: Sand production, aggregate shaping, or recycling?

- Analyze Feed Materials: Hardness, abrasiveness, input size.

- Project Capacity Needs: Adjust model choices to expected output.

- Research Manufacturer Service: Spare part availability, training, on-site support.

- Assess Energy Efficiency: For long-term cost savings, check for modern units with high efficiency and smart automation.

Real-World VSI Crusher Case Study

A quarry that needed more sand started using an SBM VSI6X Sand Maker. Within a year, the amount of useful sand increased by 30%, and the cost to make each ton dropped by 18%.

Frequently Asked Questions

Conclusion

Choosing the right vertical shaft impact crusher doesn’t have to be confusing. By knowing what details matter and focusing on long-term efficiency—and by choosing a trusted company like SBM—business can get better results, reduce stoppages, and earn more.