Email: [email protected]

Gypsum Crusher

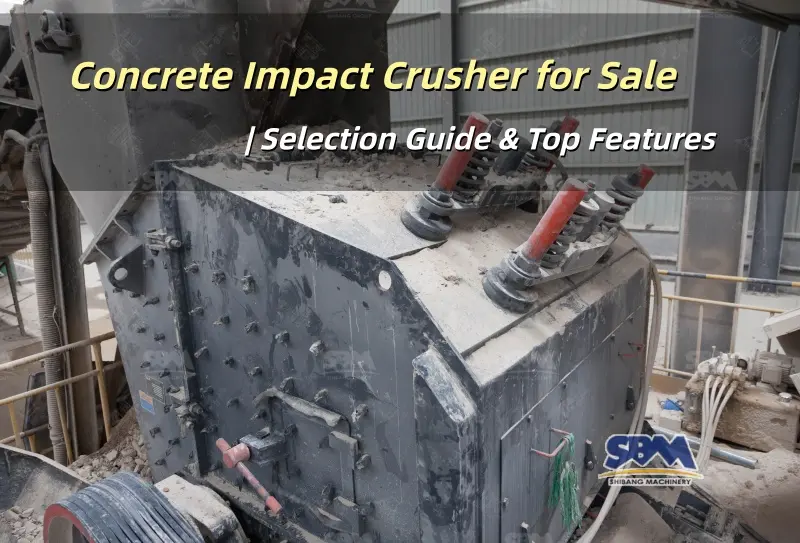

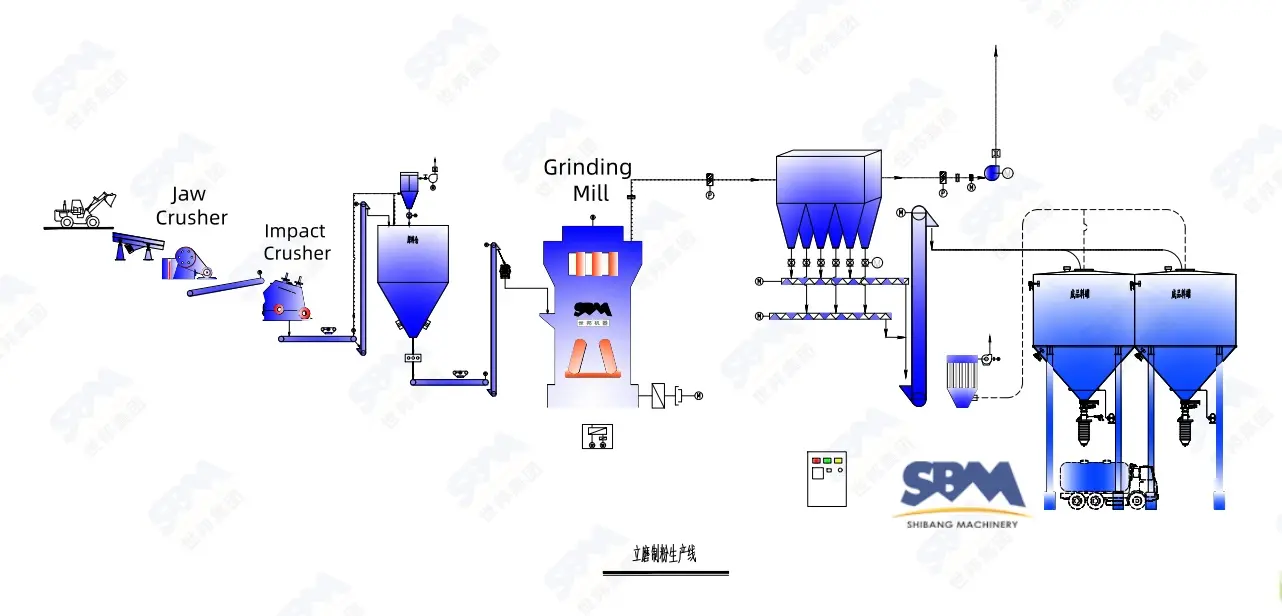

SBM gypsum crusher is key equipment for crushing large gypsum ores. It turns them into small pieces efficiently. We also provide portable and mobile crusher based on customer requirements. Gypsum crushers are ideal for medium and small-sized materials, such as clinker, sand, coal, and other minerals. Shanghai SBM offers various types, including jaw, cone, impact, and mobile gypsum crusher. These machines use advanced domestic and international crushing technology. Besides crushers, Shanghai SBM also manufactures gypsum mills and related auxiliary equipment for gypsum processing.

Types and Applications of SBM Gypsum Crushers

A gypsum crusher is a machine designed to crush large gypsum ores into smaller sizes. Shanghai SBM is a top manufacturer and supplier of gypsum crusher in China. We produce primary and secondary jaw crusher, impact crusher, hydraulic crusher, and four types of cone crusher for gypsum crushing. Portable and mobile crusher are also available to meet diverse customer needs.

SBM gypsum crushers use the latest crushing technology from home and abroad, like impact and hammer systems. They are mainly used to crush gypsum, cement raw materials, sand clinker, iron ore, coal, and other minerals. They also work well in hard-to-reach places.

Shanghai SBM focuses on gypsum crusher machines and full crushing plants. We provide fixed and mobile solutions, including jaw, cone, and impact crusher, along with mobile screening plants. Our mobile crusher is very popular with customers. If you want to buy a gypsum crusher in India or Russia, SBM is your best choice for efficient gypsum processing.

Product Comparison: SBM Gypsum Crushers

| Model | Max Feed Size (mm) | Capacity (t/h) | Power (kW) | Typical Output Size (mm) | Key Features |

|---|---|---|---|---|---|

| CI5X1110 | 500 | 110-260 | 160-200 | <40 | High efficiency, hydraulic adjust |

| CI5X1213 | 550 | 145-350 | 200-250 | <35 | Robust rotor |

| CI5X1315 | 600 | 200-450 | 250-315 | <30 | Advanced tech |

| CI5X2023 | 1300 | 1000-2100 | 1000-1260 | <20 | Heavy-duty, large scale |

All models are suitable for gypsum and similar minerals, with quick adjustment features and reliable spare part support.

Visualizing Your Gypsum Crusher Decision

| Key Factor | Why It Matters | SBM Solution |

|---|---|---|

| Crushing Efficiency | Higher output, lower energy cost | Heavy-duty rotors, smart hydraulics |

| Adjustability | Different material, size needs | Tool-free discharge gap adjustment |

| Maintenance Simplicity | Minimizes downtime, long equipment life | Digital parts, global support network |

| Spare Parts Availability | Ensures production isn’t interrupted | Localized spares, fast shipping |

| Automation | Reduces labor, improves safety & accuracy | Automated systems, remote monitoring |

What to Consider When Buying a Gypsum Crusher

Material Hardness and Moisture

Gypsum’s Mohs hardness is low, so both impact crusher and jaw crusher are effective. For wet or sticky material, choose a design with easy cleaning and wide discharge.

Capacity & Throughput

Calculate the required tons per hour (TPH). Oversizing can waste energy, but undersizing leads to poor productivity. Reference SBM models for flexible throughput ranges fit for both small operations and high-capacity tasks.

Particle Size Output

What is your target size? For fine powder production, select a crusher with adjustable discharge or one integrated with a mill.

Automation and Maintenance

Hydraulic controls and easy access to spare parts are important for less downtime. SBM crusher is built for tool-free part changes, fast adjustments, and quick access to needed supplies.

Reliability and Support

Consider suppliers offering not just equipment, but comprehensive onsite support, spare parts, training, and after-sale service. Brand reputation, like SBM’s, adds confidence and ensures continuity.

Buyer’s Cheat Sheet: Must-Ask Questions

- What’s the maximum size of my raw gypsum?

- What exact size and amount of output do you need?

- Do you need mobile or fixed equipment at your site?

- Are you ready for setup and daily upkeep?

- How do I access quick technical support and parts?

Using these questions during quotes and negotiations can keep suppliers responsible and secure you the best deal.

Frequently Asked Questions (FAQs)

Absolutely! Impact crusher, like those made by SBM, can also be used to crush materials such as limestone, barite, dolomite, and talc.

For heavy use or multiple work shifts, automatic hydraulic systems make daily tasks faster, lower labor costs, and keep machines running longer.

SBM not only provides machines, but also offers help with site setup, training, parts supply, and local support to ensure smooth and worry-free long-term use.

Follow the machine guide for oil types. Usually, ISO 150 or specific hydraulic oils are suggested for crusher parts to keep the machine running smoothly and lasting longer.

Overheating can happen because of blocked oil coolers, problems with the lubrication system, or mechanical faults. Checking oil temperature, pressure, and crusher load every day helps stop overheating.

Causes include loose bolts, material buildup on parts, worn counterweights, or damage to the structure. Regular checks and upkeep help fix this problem.

Expanded Gypsum Crusher FAQs

Common reasons are worn manganese liners or sudden changes in the type of feed material, which can cause blockages or lower crushing performance.

Lockup is often caused by unwanted materials—things like metal or wood that can’t be crushed getting into the crusher. Removing these materials and keeping a steady flow of lubrication helps stop lockups.

Regularly checking worn parts, servicing the lubrication system, cleaning filters, and keeping a maintenance record are all important for reliable performance.

Calibrate crusher settings and screens, monitor production quality daily, and adjust feed and discharge parameters as needed to maintain uniform output size.

Operators should wear hard hats, safety glasses, ear protection, and gloves. Following lockout/tagout procedures during maintenance ensures safety around moving parts.

For heavy or long work shifts, automation cuts down on work, boosts running time, and makes work safer. Hydraulic controls and remote monitoring are common automated features in today’s crushers.

Operators must control dust, air pollution, noise, and waste properly by following air and water quality rules to avoid fines and protect nearby areas.

Got More Questions? We’re Here to Help!

If you have any specific concerns, technical queries, or need advice on choosing the right gypsum crusher for your operation, don’t hesitate to reach out. Our team of experts is ready to provide personalized support and answer any questions you might have.