Email: [email protected]

From Rubble to Resources: How Jaw Crushers Are Revolutionizing Concrete Recycling Worldwide

Picture this: A demolished office tower in Berlin becomes the foundation for a new eco-friendly housing complex. A collapsed bridge in Texas provides raw material for highway repairs. This isn’t sci-fi—it’s the power of modern jaw crushers in recycling concrete and demolition waste. Let’s explore how this technology is turning 230 million tons of annual global construction waste into valuable assets.

The Concrete Recycling Challenge (and Why Jaw Crushers Win)

Problem 1: The “Dirty Secret” of Demolition

Concrete waste often contains rebar, wood, and even hazardous PAHs. Traditional crushing methods struggle with contamination.

Jaw Crusher Solution

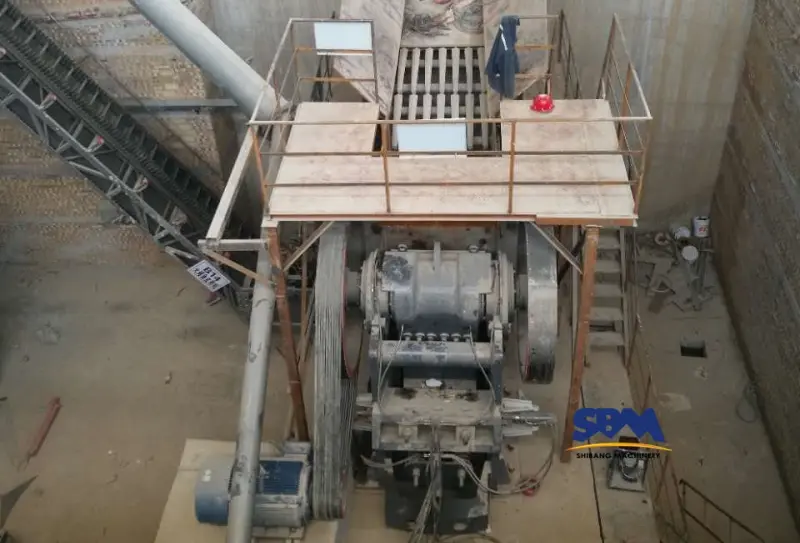

Modern units like SBM’s C6X series feature:

- Magnetic separators for automatic rebar removal

- Dust suppression systems meeting EU emission standards

- Hardox® steel jaws crushing 500MPa concrete

Global Success Stories

Case Study 1: London’s Crossrail Project

Used mobile jaw crushers to process 3.2M tons of tunnel spoil:

| Metric | Result |

|---|---|

| Recycled Aggregate | 92% of total waste |

| Cost Savings | £18M vs landfill |

| CO₂ Reduction | Equivalent to 7,500 car-years |

Case Study 2: Dubai’s Sustainable Skyscrapers

Stationary jaw crushers process 800t/day of demolition debris for:

- Structural concrete (40MPa grade)

- Landscaping gravel

- Road base materials

Optimizing Your Setup: Pro Tips

Feed Size Matters

For efficient gravel production:

- Pre-screen debris >500mm

- Adjust CSS to 50-75mm for optimal shape

Maintenance Hacks

Avoid common failures:

- Rotate jaws every 400 operating hours

- Use laser alignment for 0.2mm precision

The Technology Edge: 2025 Innovations

- AI-Powered Sorting: Real-time material analysis via camera systems (tested in Netherlands recycling plants)

- Hydro-Crush Tech: Water-assisted crushing reduces dust by 70% (patented by SBM)

Choosing Your Champion: PE vs C6X Series

PE Series

Best for:

- Small-scale recycling (<200t/day)

- Temporary urban demolition sites

C6X Series

Best for:

- Mining-level volumes (>1,000t/day)

- High-abrasion concrete with rebar

Still unsure? Use our interactive selector tool.

Regulatory Smarts: Staying Compliant

Key global standards for recycled aggregates:

- EU: EN 12620 (max 1% lightweight impurities)

- USA: ASTM D2940 (gradation requirements)

- Germany: R-Beton certification

Future Forecast: The 2030 Recycling Landscape

With next-gen jaw crushers, experts predict:

- 95% concrete recycling rates in EU cities

- 50% reduction in aggregate mining

- Carbon-negative concrete production via CO₂ injection tech

Conclusion: Crushing the Linear Economy

From Berlin to Boston, jaw crushers are proving that demolition waste is just mislabeled raw material. As SBM’s R&D lead puts it: “The best recycling plants aren’t factories—they’re the jaws of progress.”