Email: [email protected]

How to Reduce Wear When Crushing Granite: Jaw, Cone and Impact Solutions

Crushing granite is profitable but tough on your equipment. The same hardness that makes granite a premium aggregate also accelerates wear on crushing parts. It quickly wears jaw plates, cone liners, and impact blow bars in granite applications. Reducing wear is the fastest way to cut your cost per ton. It also keeps the plant running longer with fewer shutdowns and interruptions. So how to reduce wear when crushing granite?

Why Granite Causes High Wear?

Granite is a hard, silica‑rich rock with high compressive strength and strong abrasiveness. In practice this means:

- Metal surfaces in the chamber (jaw plates, mantles, concaves, blow bars) are constantly “sand‑blasted” by sharp particles.

- Any mis‑alignment, over‑tight CSS or excessive fines recirculation accelerates local wear and leads to grooves and cracks.

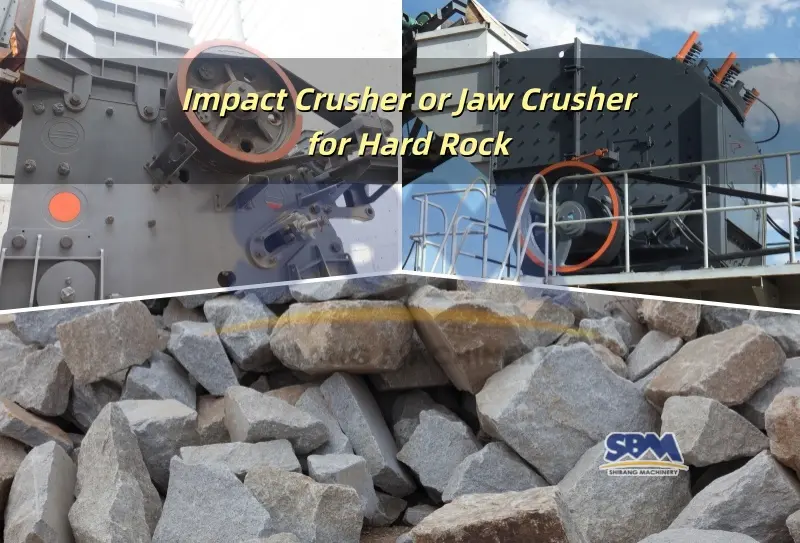

Understanding this explains why compression-type machines, such as PE jaw crushers and cone crushers, handle the main crushing duty. High-speed impact crushers are then used more selectively for shaping the final product.

Reducing Wear in Granite Jaw Crushing

Practical tips:

- Choose the right jaw profile: For hard, abrasive granite, a heavy‑duty, deep‑tooth profile with sufficient manganese content usually offers better life than very sharp, thin teeth.

- Set a reasonable CSS: Over‑tight CSS increases crushing pressure and localizes stress on small contact areas, which accelerates jaw plate wear and can overload the toggle system.

- Control feed size and fines: Avoid feeding oversize boulders or excessive fines; both extremes increase uneven wear. Use a grizzly feeder to remove soil and small fines before the jaw.

- Flip and rotate plates on time: Plan regular inspections and flip jaw plates before deep ridges form. Changing too late wastes steel and risks cracking.

These measures let your PE jaw run longer between changes, stabilizing the primary stage for the rest of the granite line.

Reducing Wear in Granite Cone Crushing

Key practices:

- Correct chamber selection. Use chambers specifically designed for hard rock, with proper nip angle and choke feed capability. Using the wrong chamber profile causes point loading and leads to uneven liner wear.

- Maintain choke feed. A well‑filled chamber spreads the crushing load across the full liner surface, reducing localized wear and improving product shape.

- Optimize CSS and stroke. Too small a CSS or unsuitable stroke can increase fines and circulating load, which both raise wear rates. Tuning settings to your target product curve reduces unnecessary grinding.

- Use proper liner material and thickness. High‑manganese steel or manganese with alloy additions is typically chosen for granite; very thin liners may flex and crack under hard‑rock loads.

Managing Wear in Impact and VSI Shaping

To keep wear under control:

- Avoid using impact as the main primary for very hard granite. Let the PE jaw or cone take the hardest work; use impact or VSI mainly for final shaping.

- Feed pre‑screened, well‑graded material. Remove soil, extreme oversize and tramp metal; dirty or poorly controlled feed can destroy blow bars or rotor tips quickly.

- Limit shaping to high‑value fractions. If only certain sizes need premium shape (for example 5–20 mm concrete aggregate), bypass other fractions to save wear.

- Monitor wear patterns. Uneven wear on one side of the rotor or anvils usually indicates mis‑aligned feed or incorrect rotor speed. Early correction prevents catastrophic failures.

For a full comparison of jaw, cone and impact roles in granite, see our ‘Granite Crusher Machine’ guide.

Operational Strategies to Cut Granite Wear and Cost per Ton

In addition to selecting the right equipment and cavity type, daily operation and maintenance also have a huge impact on wear, which can be summarized into several “on-site executable” strategies:

- Keep feed continuous and stable: Large fluctuations in feed rate cause uneven wear and more mechanical stress.

- Train operators on wear indicators: Teach them how to read liner thickness, spot abnormal vibration or temperature, and schedule changes before failures.

- Use proper lubrication and sealing: Dust from granite is fine and abrasive; good seals and clean grease or oil slow down bearing and shaft wear.

- Record wear vs production: Track how many tons each set of jaw plates or liners produces. This data lets you compare materials, settings and suppliers with real numbers.

You can visit this article “Granite Crushing Plant” to learn about the related configuration and process.

FAQs About Wear in Granite Crushing

Granite typically contains more hard minerals like quartz and feldspar, giving it higher compressive strength and abrasiveness. These sharp, hard particles act like sandpaper on jaw plates, cone liners and blow bars, so wear progresses faster than in softer, less abrasive rocks.

There is no universal interval, because wear depends on feed size, abrasiveness, settings and operating hours. However, many hard‑rock plants inspect plates weekly and flip them when ridges become deep. Tracking tons produced per set over time gives a more reliable change schedule than simply using calendar days.

For many granite producers, high‑quality manganese or alloyed liners pay back quickly. If a premium set of jaw plates or cone liners runs 30–50 % longer and reduces unplanned downtime, the extra purchase price is usually outweighed by lower cost per ton and more stable production.