Email: [email protected]

Granite Crushing Plant: Complete Crusher Solutions for Hard Stone

A granite crushing plant is more than just a single crusher – it is a complete system designed to turn very hard, abrasive granite into profitable aggregates for concrete, asphalt, and roadbase. A well‑designed plant combines the right primary, secondary, and tertiary machines with a practical layout and reliable auxiliary equipment.

In this article, you will see how to design a granite crushing plant from 100 to 500 tph, how it connects with the previous guides “Best Jaw Crusher for Granite”, “Granite Crusher Machine”, and “200 TPH Granite Crushing Plant Design”, and what information you should prepare before requesting a customized solution.

Why Granite Needs a Dedicated Crushing Plant?

Granite has high compressive strength and strong abrasion, so it quickly wears out under‑sized or poorly chosen crushers. Compared with softer rocks, it:

- Requires a strong compression‑type primary (typically a PE series jaw crusher).

- Benefits from cone crushers in secondary for laminated crushing and stable gradation.

- Often needs selective shaping (impact or VSI) to meet high‑spec concrete and asphalt requirements.

Because of this, a dedicated granite crushing plant usually follows a classic structure: feeder → PE jaw → cone (one or two stages) → screen → optional impact/VSI → stockpiles.

Core Machines in a Granite Crushing Plant

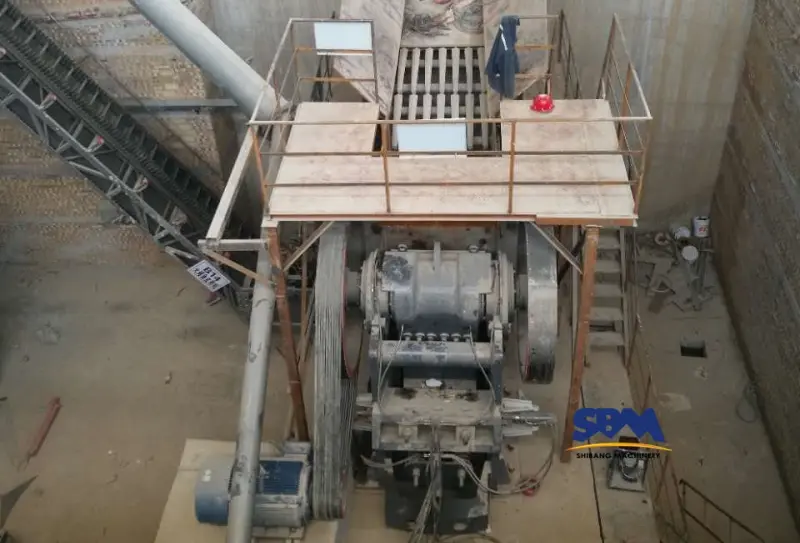

1. Primary: PE Series Jaw Crusher

The PE jaw crusher is the “first gate” of the granite plant. It handles large boulders directly from blasting or dumping and reduces them to a manageable size for downstream machines. This part is fully discussed in your “Best Jaw Crusher for Granite” article, which explains:

- Why PE jaw crushers are ideal for hard, abrasive granite.

- How to choose the right feed opening and capacity (e.g., PE600×900, PE750×1060, PE900×1200).

Here, the jaw works as the backbone of the entire plant, so getting this choice right is the first step of design.

2. Secondary: Cone Crusher

Cone crushers take the 0–150 mm (or similar) product from the jaw and crush it further down to about 0–40 mm. They:

- Use laminated compression, which fits granite’s hardness and abrasiveness.

- Offer good balance between reduction ratio, liner life, and energy efficiency.

3. Tertiary / Shaping: Impact or VSI

Not every granite plant needs a tertiary stage, but when customers demand premium cubical aggregates or manufactured sand, a secondary impact or VSI unit is added:

- Horizontal shaft impact (HSI) crushers produce good shape but with higher wear in very abrasive granite.

- VSI (vertical shaft impact) crushers use “rock‑on‑rock” impact, often preferred for fine shaping and sand.

Typical Granite Crushing Plant Setups (100–500 TPH)

1. Around 100–150 TPH: Compact Granite Plant

- Feeder + hopper

- PE600×900 (or similar) jaw crusher

- Single‑cylinder or small multi‑cylinder cone

- 3‑deck vibrating screen (e.g., 0–5, 5–10, 10–20, 20–30 mm)

This setup suits small quarries or contractors supplying local concrete plants and road projects.

2. 200 TPH: Standard Granite Plant

This is the configuration already detailed in the “200 TPH Granite Crushing Plant Design” article, but summarized here to keep the series cohesive:

- Vibrating feeder with grizzly bars

- PE750×1060 jaw crusher as primary

- Medium‑size cone crusher as secondary

- 3‑deck vibrating screen

- Optional VSI / impact for shaping 0–20 mm

You can visit the dedicated page for the 200 tons per hour capacity design to view detailed process flow diagrams, equipment lists, and layout specifications.

3. 300–500 TPH: High‑Capacity Granite Plant

- Heavy‑duty feeder and large hopper

- PE900×1200 or PE1200×1500 primary jaw

- Two‑stage cone system (coarse cone + fine cone)

- One or two vibrating screens depending on number of final sizes

- Optional VSI for premium shaped materials and sand

Such lines are typically used by big aggregates companies serving multiple concrete batching plants and highway projects.

Stationary vs Mobile Granite Crushing Plants

For granite, most high‑capacity operations prefer stationary plants because of higher throughput and lower cost per ton. However, mobile or semi‑mobile units can make sense when:

- The deposit is spread out and relocation saves haulage cost.

- Projects are temporary (e.g., road construction contracts).

A hybrid approach is common: stationary PE jaw and cone for main production, plus a mobile impact or mobile cone used as a flexible satellite crusher for specific projects or extra shaping.

FAQs About Granite Crushing Plants

Most granite plants use at least two crushers: a primary PE jaw crusher and a secondary cone crusher. For higher product shape requirements or manufactured sand, a third stage (impact or VSI) is often added as a shaping step.

Many global investors start from 100–200 tph because this range balances investment with market demand. A 200 tph line is large enough to supply multiple concrete plants yet still manageable in terms of CAPEX and operating complexity.

Yes. A well‑planned layout allows you to add an extra cone or VSI crusher, or upgrade to a larger PE jaw model, without rebuilding everything. When designing the first plant, it is wise to reserve space on foundations and conveyors for future expansion.