Email: [email protected]

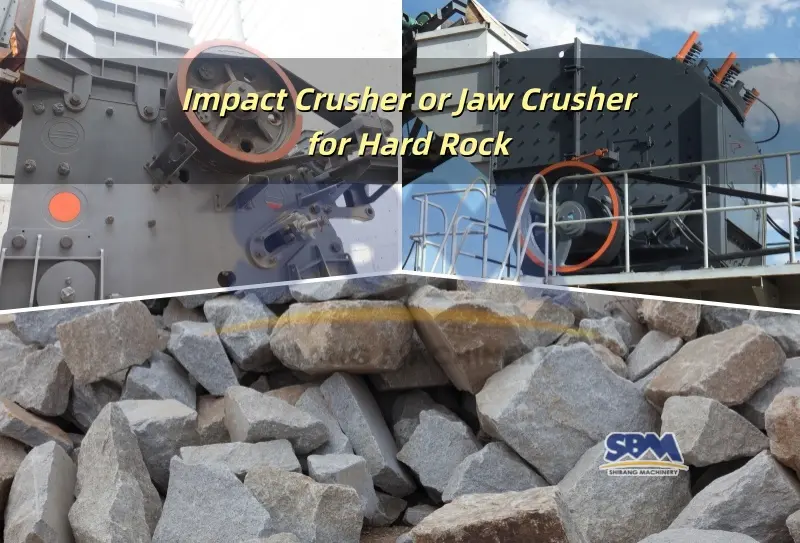

Jaw Crusher for Sale: Pricing, Types & Buying Guide

Searching for a jaw crusher for sale? This practical guide explains every detail you need—from the latest market trends to essential buying tips—so you can make the smartest investment for your mining or construction needs. Let’s jump in!

Why Jaw Crushers Matter in Mining?

Jaw crusher plays a key role in breaking large pieces of ore or rock into smaller ones. They are the main machines used in mining and quarrying, providing reliable, high-capacity crushing for the first stage of material reduction. If you want to process minerals efficiently, having a good jaw crusher is very important.

How Jaw Crushers Work?

A jaw crusher uses a motor to drive a swinging jaw against a fixed jaw. The ore or rock gets trapped and crushed into smaller pieces as the moving jaw moves back and forth.

Key Components of Jaw Crusher

| Part | Function |

|---|---|

| Fixed Jaw | Stationary crushing surface |

| Moveable Jaw | Swings back and forth to crush ore |

| Eccentric Shaft | Converts motor rotation to movement |

| Toggle Plate | Provides force and protects unit |

| Flywheel | Stores energy and evens movement |

| Adjustment Device | Sets output particle size |

These parts work together to deliver the powerful, continuous crushing action manufacturers and site operators count on every single day.

Which SBM jaw crushers are available for sale?

SBM offers the following jaw crushers for sale:

PE Jaw Crusher

- Input Size: 0-1020 mm

- Capacity: 45-800 TPH

- Suitable Materials: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore

- Features: Classic, stable performance, high-quality manganese steel parts for longer service life, precise processing, overload “power failure” safety device, various models for different production scales

- Models range from PE500×750 to PE1200×1500 with capacities from 45 to 900 tons per hour

- Working principle: Motor-driven eccentric shaft moves the jaw to crush materials, discharged at the bottom

PEW Jaw Crusher

- Input Size: 0-930 mm

- Capacity: 12-650 tons per hour (TPH)

- Suitable Materials: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore

- Automatic hydraulic design: makes adjusting and using the machine simple

- Stable Structure: Uses high-quality steel parts for core key areas like the moving jaw and bearing block. This means the parts fit well, connect smoothly, stay strong, work reliably, and last a long time.

- Digitalized Processing: High precision manufacturing of parts with numerical control cutting, bending, milling, and painting

- Hydraulic chamber cleaning: comes with a hydraulic oil station for proper lubrication and a system that quickly clears out the crushing space when the machine stops, which saves time.

- Wide, V-shaped crushing space and specially designed guard board: gives more room to crush, keeps material from piling up, boosts how much it can crush, and helps the jaw plates last longer.

- Wedge Discharging Adjustment Device: Enables quick discharge port adjustment (within minutes) even when idling; safer and simpler compared to traditional devices, with options for automation via hydraulic system

- Spare Parts Supply and Support: SBM offers technical support and original parts to ensure worry-free operation and long machine life

C6X Jaw Crusher

- Input Size: 0-1280 mm

- Capacity: 160-1510 TPH

- Suitable Materials: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore

- Features: Modern design and good efficiency, easy to set up, strong cast parts, simple grease lubrication, quick and easy output adjustment using mechanical or hydraulic controls.

- Models range from C6X80 to C6X200 with capacities from 80 to 1510 tons per hour

- Designed for higher crushing efficiency and easier maintenance

Key Features Buyers Should Consider

When shopping for a jaw crusher for sale, keep these decisive features in mind:

- Capacity: How many tons per hour does it process? Match this to your production needs.

- Feed Opening Size: Can it handle the maximum size of your material?

- Discharge Adjustment: How precisely can you set your output sizes?

- Energy Efficiency: Look for updated machines with lower power consumption and energy-saving features.

- Maintenance Access: Is routine service straightforward and safe?

- Safety Features: Emergency stops, proper guards, and user-friendly controls are non-negotiable.

- Durability: Opt for robust construction (heavy-duty frames, quality steel) for maximum uptime.

Typical Jaw Crusher Applications

Jaw crushers work best in these main areas:

- Hard rock mining (gold, copper, iron ore)

- Gravel and other small stones

- Concrete and construction recycling

- Demolition washdowns

- Laboratory ore sampling

It’s practically impossible to run a modern quarry or mine site without one in the lineup.

Prices for Jaw Crushers in 2025

Jaw crusher price depends on size, technology, brand reputation, and where you buy. Here are ballpark figures:

| Crusher Category | Price Range (USD) |

|---|---|

| Mini/Lab Crushers | $1,000–$5,000 |

| Standard Single Toggle | $5,000–$100,000 |

| Heavy Duty/Double Toggle | $50,000–$200,000+ |

| Mobile (Track-mounted) | $90,000–$500,000+ |

Used jaw crusher can offer serious savings, but always check wear and source parts from reliable suppliers.

Tips for Finding the Best Jaw Crusher for Sale

Choosing the right jaw crusher can feel like a big job, but here are some important tips you shouldn’t miss:

- Buy from a trusted maker or dealer, not from unknown sellers.

- Double-check warranty and after-sales support.

- Analyze your application—don’t just buy the biggest or cheapest crusher.

- Read reviews and what other users say.

- Ask for a full equipment inspection, especially if buying used.

- Understand the shipping, setup, and spare parts delivery times.

Personal tip: Look for easy-to-use adjustment systems and real feedback. Hearing from people who use the machine already is the best help.

Jaw Crusher Maintenance and Longevity

A jaw crusher only delivers value if it runs reliably for years. Here’s how to keep yours in peak condition:

- Regularly inspect wear parts (jaws, toggle, eccentrics).

- Grease and lubricate all moving parts per the OEM guide.

- Replace worn parts promptly to avoid catastrophic breakdowns.

- Train your operators—simple errors cause most failures.

With proper care, a modern jaw crusher will outlast several generations of operators and consistently boost your plant’s productivity.

Frequently Asked Questions About Jaw Crushers for Sale

What’s the difference between jaw crusher types?

Single toggle models are simpler and dominant, while double toggle models cater to heavy-duty needs.

Is a mobile jaw crusher right for me?

If you’re moving sites often or want versatility, track-mounted crushers are now very popular.

How do I pick the right model?

Choose based on your material type, desired output, production targets, and available budget.

Are used jaw crushers a good investment?

They can be, if sourced from a trusted dealer with honest maintenance records and available spares.

What about safety?

Always confirm your machine includes latest safety features: guards, auto-stops, and clear controls.

Where to Buy: Jaw Crusher For Sale Sources

Major makers and suppliers of industrial machines sell brand-new equipment as well as factory-refurbished options. Well-known companies like SBM and Zenith have strong reputations for quality and good customer support.

For buyers worldwide, the best places to source these machines are Asia-Pacific (especially China and India), North America, and Europe. Buyers often mention competitive prices and reliable customer service as the main reasons they are happy with their purchase.

Conclusion

Whether you’re establishing a new processing line or upgrading for 2025, choosing the right jaw crusher for sale is critical for maximizing your ROI. Look beyond the price tag: focus on features, support, and application fit for best results. And don’t be afraid to ask questions—help is just a call or click away!